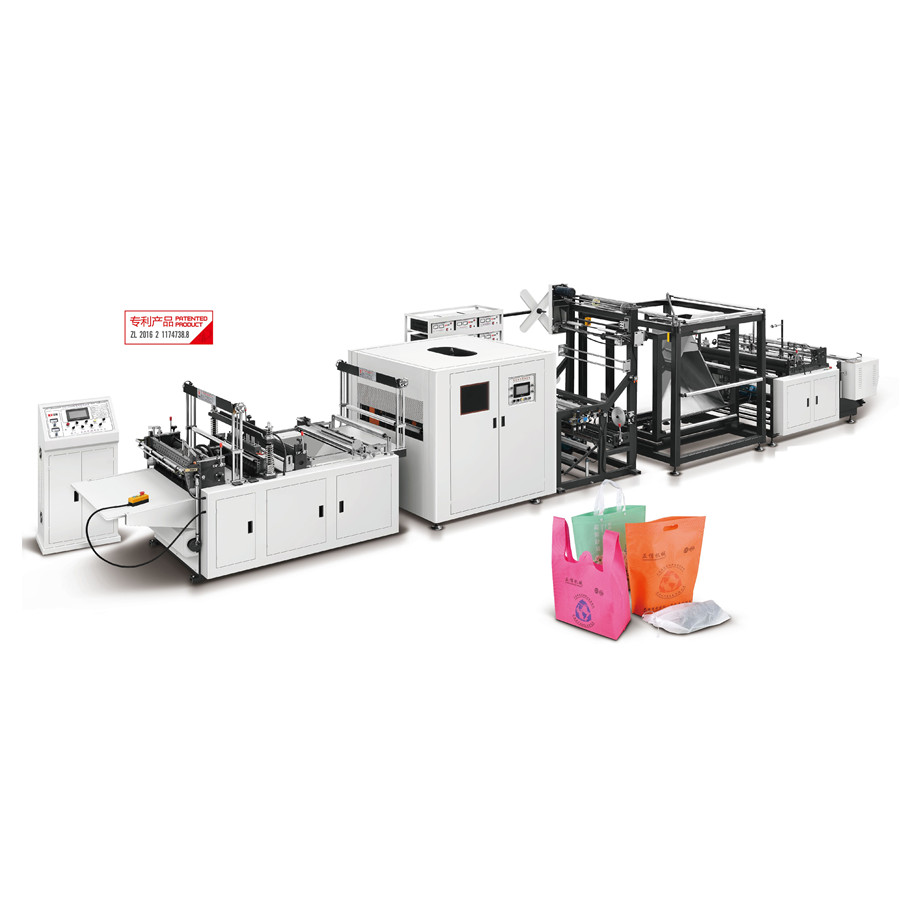

Ps Foam Plate Machine Factories – Food container production line – MACHINERY

Ps Foam Plate Machine Factories – Food container production line – MACHINERY Detail:

Main parameters

|

Item |

Unit |

Parameter |

Remark |

| Model |

FS-FPP75-90 |

||

| Applicable materials |

GPPS granule |

||

| Thickness of product |

mm |

1-4 |

|

| Width of sheet |

mm |

540–1100 |

|

| Foaming rate |

12-20 |

||

| Bulk weight of product |

Kg/m³ |

50-83 |

|

| Thermal conductivity of product |

W/m.k |

0.021-0.038 |

|

| Output |

kg/h |

70-90 |

|

| Rated power |

Kw |

140 |

|

| Power supply |

three phase 380v/50Hz |

||

| External dimension |

mm |

24000×6000×2800 |

|

| Complete machine weight |

Ton |

About10 |

Ⅰ 75/90 PS foam sheet extrusion line includes the following components

1. Automatic feeding system

1. Feeding style

Spiral feeding

2. Main parameters

| Hopper capacity of the mixer (kg) |

300 |

|

| Motor Power of the mixer(kw) |

3 |

|

| Feeding capacity of the feeder (kg/h) |

200 |

|

| Motor power of the feeder (kw) |

1.5 |

2 The first stage extruder

1. Screw and barrel material

38CrMoAlA nitrogen treatment

2. Main motor style

AC-motors with frequency converters

⑶ Speed reducer

Extruder dedicated reducer,hard tooth surface,high torque,and low noise

⑷ Heater

Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature

⑸ Technical parameters

| Driving motor power(kw) |

37 |

|

| Diameter of screw bolt (mm) |

Φ70 |

|

| L/D ratio of screw bolt |

32:1 |

|

| Max rev of screw (rpm) |

60 |

|

| Number of heating zones |

7 |

|

| Heating power (kw) |

28 |

4 Non-stop machine hydraulic automatic replace filter system

Non-stop hydraulic quickly net changing device

Main parameters

| Oil pump motor power (kw) |

4 |

|

| Oil pump max pressure (Mpa) |

20 |

|

| Filter net quantity(piece) |

4 |

|

| Heating power (kw) |

5 The second stage extruder

1. Screw and barrel material

38CrMoAlA nitrogen treatment

2. Main motor style

AC-motor with frequency converters

⑶ Speed reducer

Extruder dedicated reducer,hard tooth surface,high torque,and low noise

⑷ Heater

Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature

⑸ Cooling and temperature-reduction style

Circulating water cooling,automatic bypass system.

⑹ Technical parameters

| Driving motor power (kw) |

45 |

|

| Diameter of screw bolt (mm) |

Φ90 |

|

| L/D ratio of screw bolt |

34:1 |

|

| Max rev of screw (rpm) |

30 |

|

| Number of heating zones |

8 |

|

| Heating power(kw) |

40 |

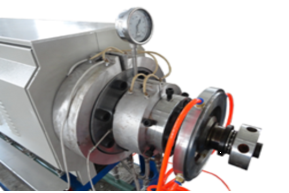

6 Extruder head and mold

1. Structure

Round of the extruder head,mold mouth can adjust,head with a pressure gauge and pressure output alarm device. The head heater with water cooling .

2. Material

:Ra0.025μm:

High quality tool steel,heat-treated,flow channel surface roughness: Ra0.025μm

⑶ Main technical data

| Diameter of mold orifice | according to the order contract |  |

| Quantity of temperature control zones |

2 |

|

| Accuracy of temperature control(℃) |

±1 |

|

| Heating power(kw) |

5 |

7 Shaping cooling and cutting system

1. Shaping style:shaping barrel

2. Cooling style:shaping barrel cools with water and external wind-ring

⑶Structure:shaping barrel, cutting knife and rack components

⑷Main technical parameters

| Shaping barrel size(mm) | According to the order contract |  |

| Blower power (kw) | Three phrase 0.55 |

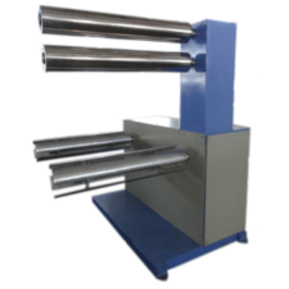

8 Pulling system

1. Pulling style:four-roller parallel pull

2. Driving motor form:AC-motor, frequency conversion velocity modulation, speed reducer changes speed

⑶ Main parameters

| Pulling roller quantity(piece) |

4 |

|

| Pulling roller size (mm) |

Φ260×1300 |

|

| Motor power(kw) |

1.5 |

9 Electrostatic elimination system

| Adopt to tod type ion rod electrostatic elimination system, working volt is 7KV above, can produce high effective and powerful ion wind, effectively eliminate electrostatic danger. |  |

10 Winding system

1. Form

Double-arm air shaft type

2. Main technical parameters

| Coiling weight(kg) | Maximum40 |  |

| Coiling diameter(mm) | Max 1100 | |

| Length control | Meter counter control, adjust length | |

| Driving motor | Torque motor 8n.m×4sets |

11 Electric control system

| extruder heating control cabinet |

One set |

|

| The second stage extruder heating control cabinet | One set | |

| winding control cabinet | One set |

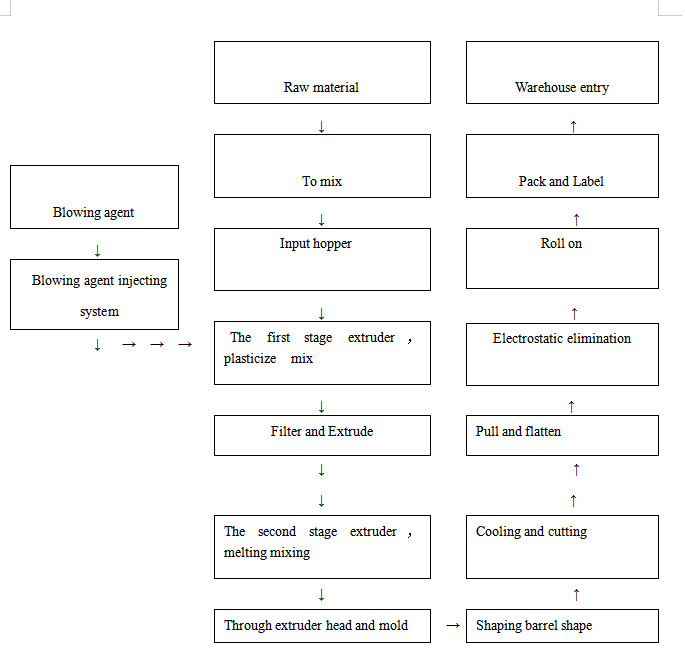

Ⅲ Production flow chart

Ⅳ Details of foam sheet extrusion line

A. Automatic feeding system

1. Feeding style

Spiral feeding

2. Main parameters

| Hopper capacity of the mixer (kg) |

300 |

| Motor Power of the mixer(kw) |

3 |

| Feeding capacity of the feeder (kg/h) |

200 |

| Motor power of the feeder (kw) |

1.5 |

B. The first stage extruder

1.Screw and barrel materials

38CrMoAlA nitrogen treatment

2. Main motor style

AC-motors with frequency converters

3. Speed reducer

Extruder dedicated reducer,hard tooth surface,high torque,and low noise

4. Heater

Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature

5. Technical parameters

| Driving motor power(kw) |

37 |

| Diameter of screw bolt(mm) |

Φ70 |

| L/D ratio of screw bolt |

32:1 |

| Max rev of screw(rpm) |

50 |

| Number of heating zones |

7 |

| Heating power (kw) |

28 |

C. Blowing agent injecting system

1. Sort of pump

Plunger type high precision and high pressure measuring pump, to match one-way valve to control, the injection volume is controlled by plunger lift

2. Main technical parameters

| Sort of blowing agent |

butane or LPG |

| Metering pump flow |

40(L/H) |

| Injection high pressure |

30(Mpa) |

| Pressure gauge |

0-40(Mpa) |

| Motor power |

3(kw) |

D. Non-stop machine hydraulic automatic replace filter system

Hydraulic quickly net changing device

Main parameters

| Oil pump motor power |

4(kw) |

| Oil pump max pressure |

20(Mpa) |

| Filter net quantity |

4(piece) |

| Heating power |

8(kw) |

E. The second stage extruder

1. Screw and barrel material

38CrMoAlA nitrogen treatment

2. Main motor style

AC-motor with frequency converters

3. Speed reducer

Extruder dedicated reducer,hard tooth surface,high torque,and low noise

4. Heater

Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature ,Cooling water device in heater .

5. Cooling and temperature-reduction style

Circulating water cooling ,automatic bypass system.

6. Technical parameters

| Driving motor power(kw) |

45 |

| Diameter of screw bolt(mm) |

Φ120 |

| L/D ratio of screw bolt |

34:1 |

| Max rev of screw(rpm) |

50 |

| Number of heating zones |

8 |

| Heating power(kw) |

40 |

F.Extruder head and mold

1. Structure

Round of the extruder head,mold mouth can adjust,head with a pressure gauge and pressure output alarm device. The head heater with water cooling .

2. Material Ra0.025μm:

High quality tool steel,heat-treated,flow channel surface roughness: Ra0.025μm

3. Main technical data

| Diameter of mold orifice |

According to the order contract |

| Quantity of temperature control zones |

1 |

| Accuracy of temperature control |

±1(℃) |

| Heating power |

5(kw) |

G. Shaping cooling and cutting system

1. Shaping style:shaping barrel

2. Cooling style:shaping barrel cools with water and external wind-ring

3.Structure:shaping barrel, cutting knife and rack components

4. Main technical parameters

| Shaping barrel size(mm) |

According to the order contract |

| Blower power(kw) |

Three phrase0.55 |

H. Pulling system

1.Pulling style:four-roller parallel pull, compress with air drive

2.Driving motor form:AC-motor, frequency conversion velocity modulation, speed reducer changes speed

3. Main parameters

| Pulling roller quantity(piece) |

4 |

| Pulling roller size (mm) |

Φ260×1300 |

| Motor power (kw) |

1.5 |

I. Electrostatic elimination system

Adopt to tod type ion rod electrostatic elimination system, working volt is 7KV above, can produce high effective and powerful ion wind, effectively eliminate electrostatic danger.

J. Winding system

1.Form

Double-arm air shaft type

2. Main technical parameters

| Coiling weight(kg) | Maximum40 |

| Coiling diameter (mm) | Max 1100 |

| Length control | Meter counter control, adjust length |

| Driving motor | Torque motor 8n.m×2 sets |

K. Electric control system

Heating control cabinet of the first stage extruder:one set

Heating control cabinet of the second stage extruder:one set

Winding control cabinet:one set

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Ps Foam Plate Machine Factories – Food container production line – MACHINERY , The product will supply to all over the world, such as: California, Canberra, Karachi, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!