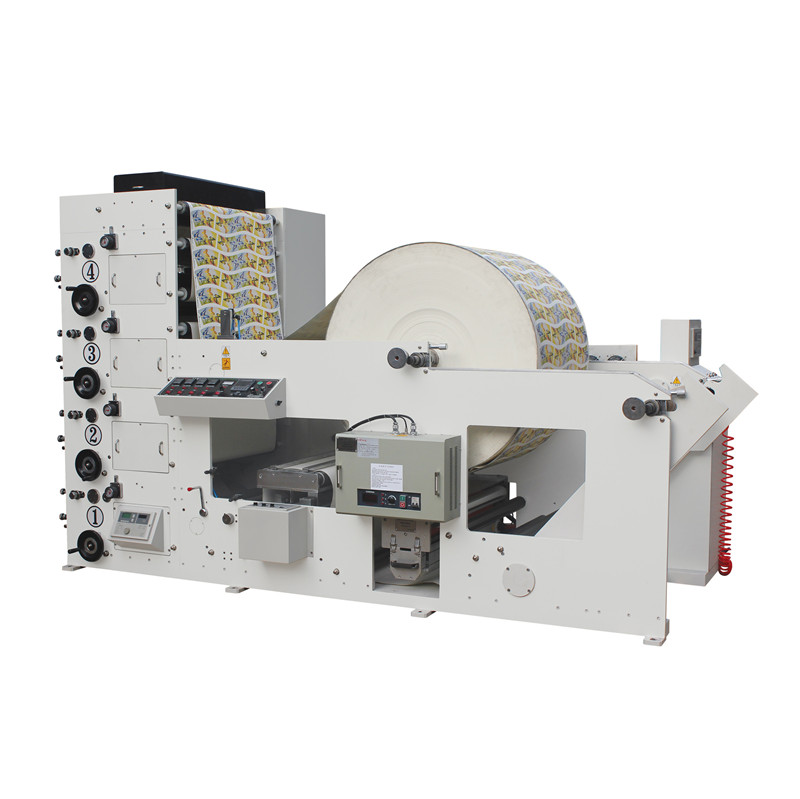

Printer Machine Factory – 4 color paper printing machine – MACHINERY

Printer Machine Factory – 4 color paper printing machine – MACHINERY Detail:

UNWINDING PART。

1. Single feeding work station

2. Hydraulic clamp,hydraulic lift the material,hydraulic control the unwinding material width,it can adjust left and right movement.

3. Magnetic powder brake auto tension control

4. Auto web guide

5.Pneumatic brake—40kgs

PRINTING PART

1. Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening,it will make alarm to start the auto lowering plate printing cylinder.

2. Inking with ceramic anilox chambered doctor blade ,ink pump circulation

3. High precision planetary gear oven 360°circulation longitudinal register

4. ±20mm transverse register

5. Adjust inking press and printing pressure press by manual

DRYING PART

1. Adopt with external heating pipe, temperature display, electric current control,centrifugal blower bring the wind

REWINDING PART

1. Back to back rewinding

2. Pneumatic tension control

3. 2.2kw motor,vector frequency conversion control

4. 3 inch air shaft

5. Hydraulic lowering the material

STRUCTURE

1. The machine adopt with synchronous belt drive and hard gear face gear box. The gear box adopt with synchronous belt drive each printing group high precision planetary gear oven(360º adjust the plate) gear driving the press printing roller(can print two sides conversion)

2. After printing, long running material space ,it can make the ink drying easily,better results

PARAMETERS

| MODEL | ZYT4-1300 |

| Max. Printing material width | 1300mm |

| Max. Printing width | 1260mm |

| Max. Unwinding diameter | 1300mm |

| Max. Rewinding diameter | 1300mm |

| Printing length range | 228-1000mm |

| Printing speed | 5-100m∕min |

| Register precision | ≤±0.15mm |

| Thickness of plate(including the thickness of double sides glue) | Customer nominated |

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Printer Machine Factory – 4 color paper printing machine – MACHINERY , The product will supply to all over the world, such as: Armenia, UK, Ottawa, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.