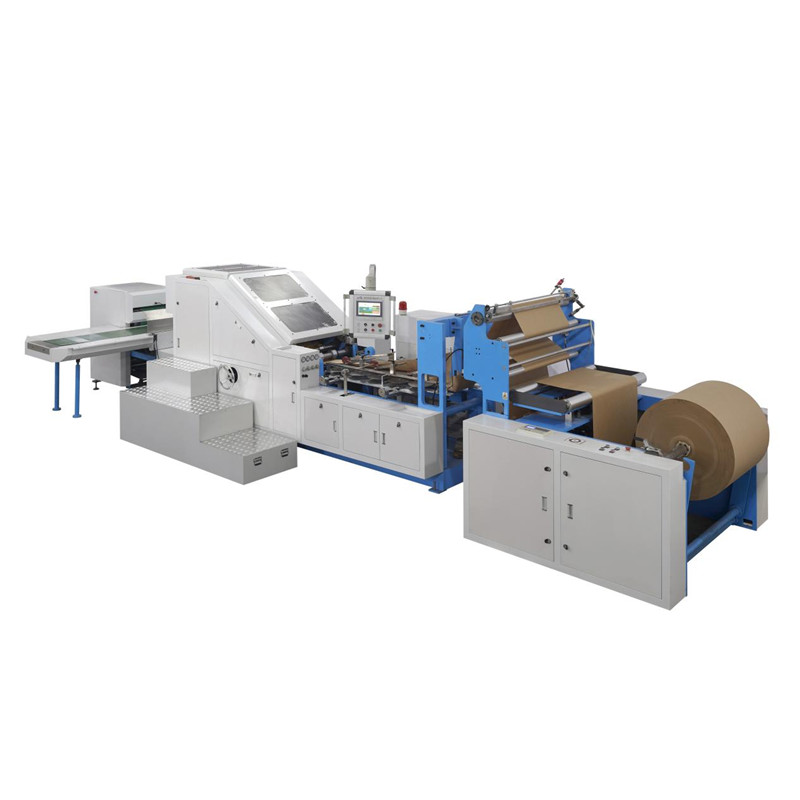

Paper Bag Making Machinery Suppliers – High speed square bottom paper bag machine – MACHINERY

Paper Bag Making Machinery Suppliers – High speed square bottom paper bag machine – MACHINERY Detail:

main feature

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts servo motor to reduce the adjustment time of paper roll alignment.

| Model | XL-FD450 |

| Cutting Length | 270-530mm |

| Paper Bag Width | 210-450mm |

| Bottom width | 90-180mm |

| Paper bag thickness | 80-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-150pcs/min |

| Paper roll width | 660-1290mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.6MPa |

| Total Weight | 9000kg |

| Overall size | 10000*3800*2200mm |

flow chart

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Paper Bag Making Machinery Suppliers – High speed square bottom paper bag machine – MACHINERY , The product will supply to all over the world, such as: Adelaide, India, Indonesia, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers' satisfaction and achieve win-win situation .

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Write your message here and send it to us