Melt Blown Making Machine Manufacturers – S non woven fabric production line – MACHINERY

Melt Blown Making Machine Manufacturers – S non woven fabric production line – MACHINERY Detail:

C. Public project

1. Water supplication

Pressure 2-4Bar

Temperature ≤28℃ PH : 6.5~9.2 Turbidity <10PPm

2. Compressed air

Operation pressure : 4-6Bar Allow range : ±0.2Bar

Dew point temperature :<25℃ Prevision : 1m3

A. Characteristics

| model no | 1600MM S | 2400MM S | 3200MM S |

| Capacity | 4-6 T/ DAY | 5-7 T/DAY | 8-10 T/DAY |

| Voltage | 240V OR 415V/50HZ | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 350 kw | 400kw | 500kw |

| Running power | 300 kw | 360 kw | 480 kw |

| effective width | 1600MM | 2400MM | 3200MM |

| Motor | Siemens | Siemens | Siemens |

| PLC | Siemens | Siemens | Siemens |

| Drive | Japan | Japan | Japan |

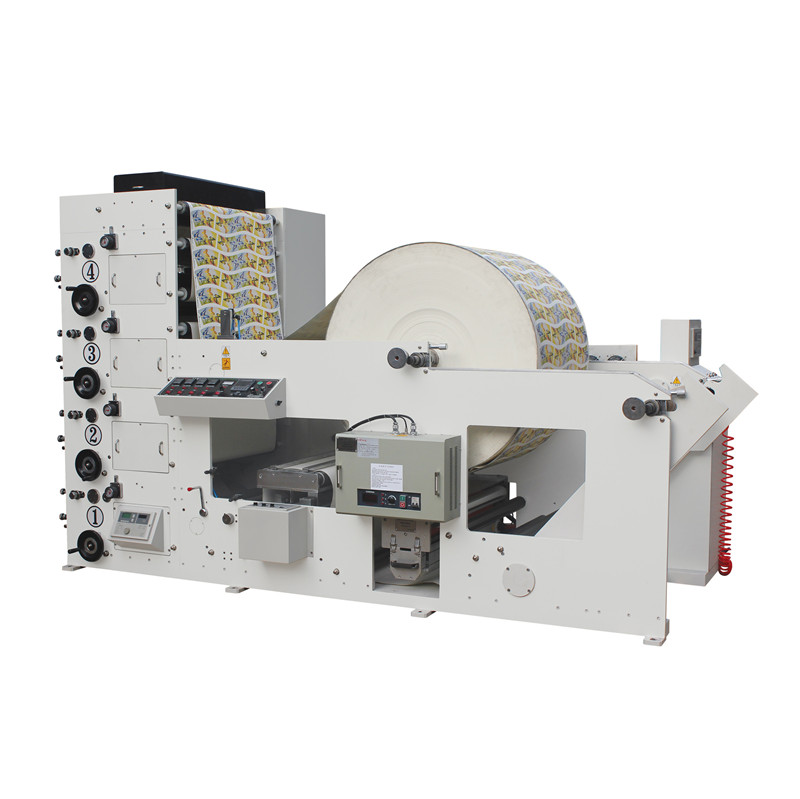

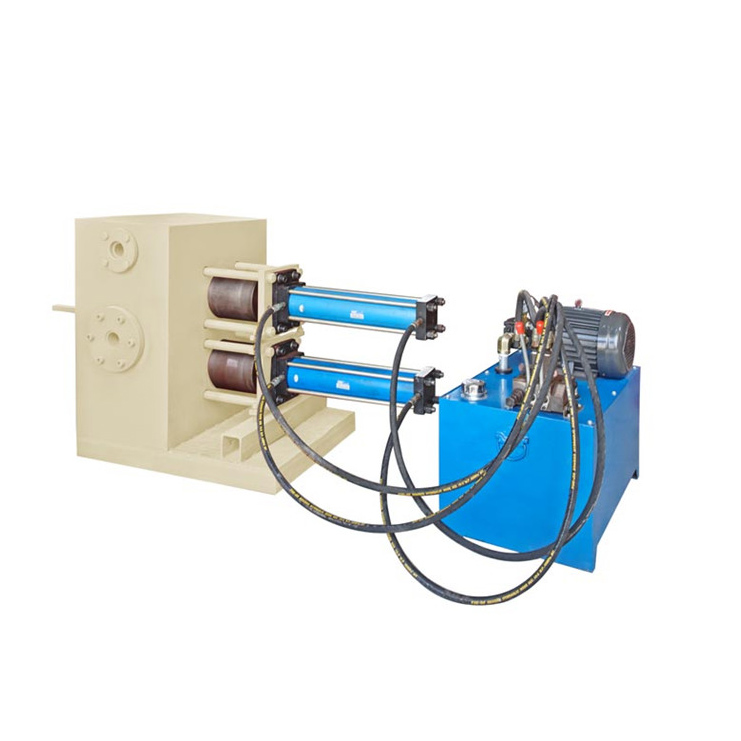

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Melt Blown Making Machine Manufacturers – S non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: Belarus, Manila, Norway, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Write your message here and send it to us