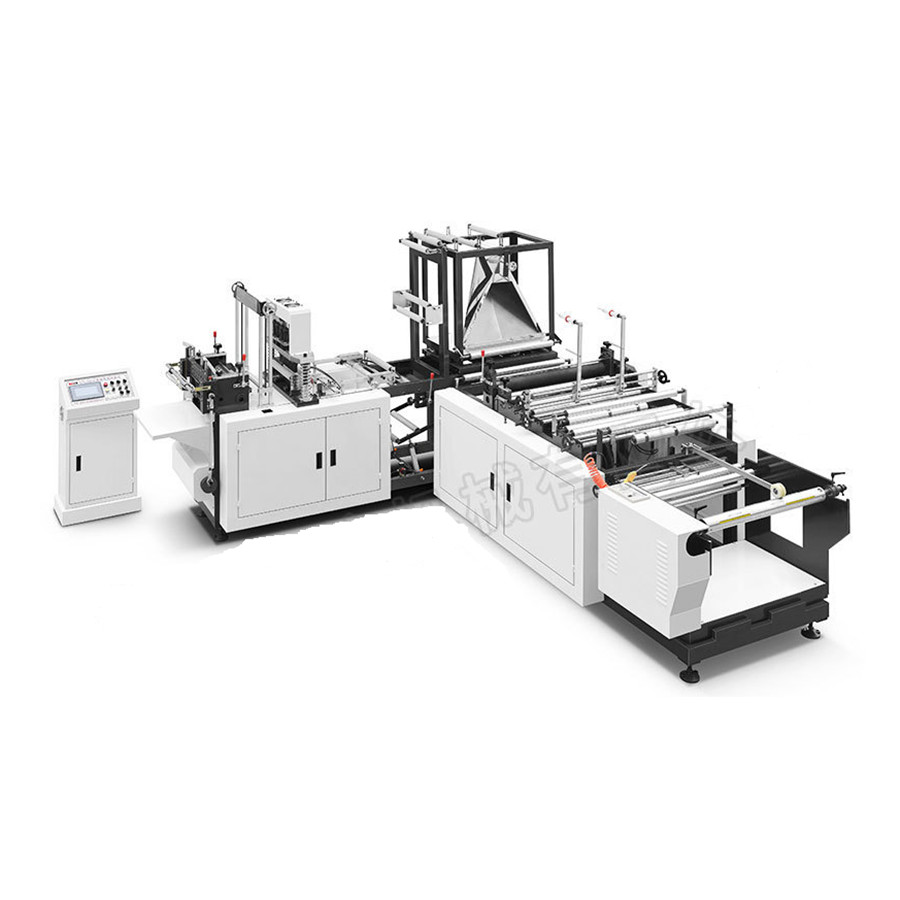

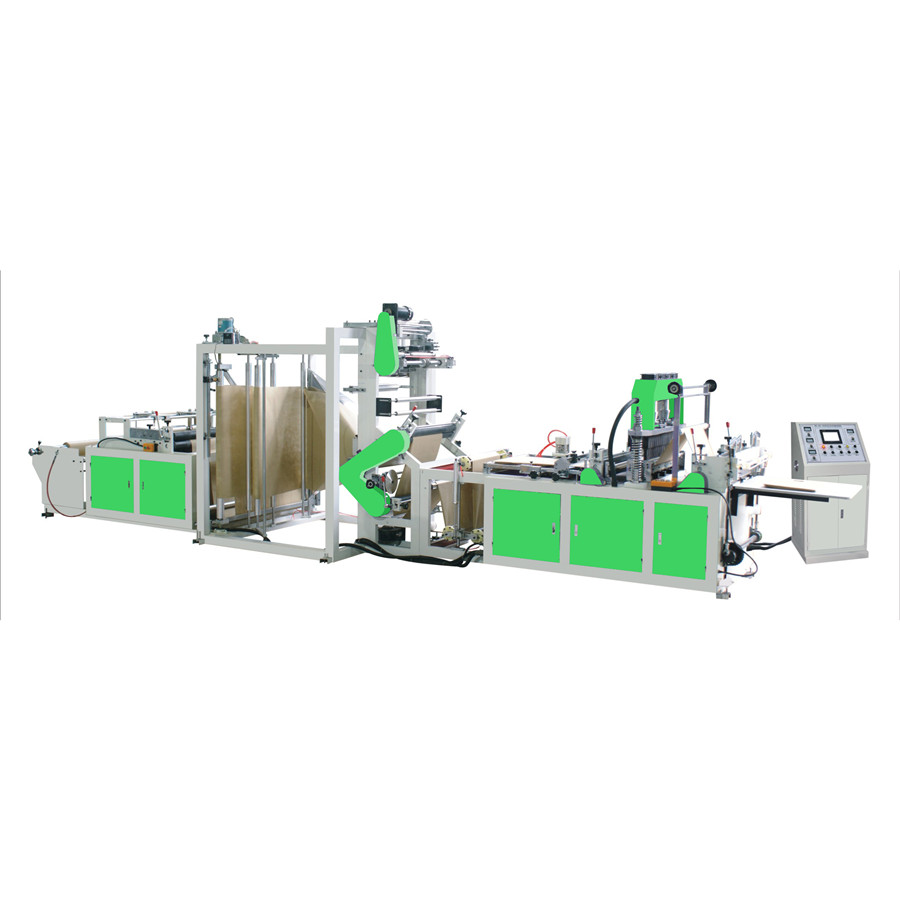

Fully Automatic Nonwoven Bag Machinery Factories – Multifunctional Non-woven Flat Bag Making Machine – MACHINERY

Fully Automatic Nonwoven Bag Machinery Factories – Multifunctional Non-woven Flat Bag Making Machine – MACHINERY Detail:

1)Fabric Roll Unwinding

Auto loading material roll(lift by cylinders) Inflatable shaft to fix the fabric roll when machine working

Auto stop when material

run out of Magnetic powder tension controller

Auto rectifying deviation system(EPC box and web guider)

Bag mouth folding and

sealing by ultrasonic welding

Cylinders to lift and fix the sealing mold

Custom-made sealing mould is available

2)Bag Bottom Gusset And Side Gusset Forming – compressed air input here

Two sets round wheels for making bag bottom gusset and side gusset

The blower removes waste fabric

T-shirt bag sealing byultrasonic welding

3)Bag Side Sealing, Cutting, Collection

Adjustable photoelectric sensor for printing color mark tracking( it can be turned on/off on the touch screen)

Online D-cut punching, drawstring bag punching bag side sealing by ultrasonic welding

Durable cold cutter

Sealing mould with heating device inside(temperature control by thermal indicator)

static eliminator device

Double stepping motor feeding system for bag length fix

Man machine interface:touch screen

Motion control:PLC

If you have different requirements, please let us know, and we will provide you with customized solutions based on the actual

situation of the machine.

Basic parameter :

| Model no | LH-B700 |

| Bag width | 100-800mm |

| Bag Height | 200-600mm |

| Fabric gsm | 30-120g/m2 |

| Running speed | 20-120pcs/min |

| Power supply | 380v/20v |

| Total power | 12 kw |

| Machine size | 7600*1900*2100mm |

| Weight | 2200kgs |

Product detail pictures:

Related Product Guide:

Our commission is to serve our users and clients with best quality and competitive portable digital products for Fully Automatic Nonwoven Bag Machinery Factories – Multifunctional Non-woven Flat Bag Making Machine – MACHINERY , The product will supply to all over the world, such as: Johor, Dubai, India, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.