China High Quality S/Ss/Sms Pp Spunbond Nonwoven Machine – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY

China High Quality S/Ss/Sms Pp Spunbond Nonwoven Machine – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY Detail:

Model: ZX-LT500

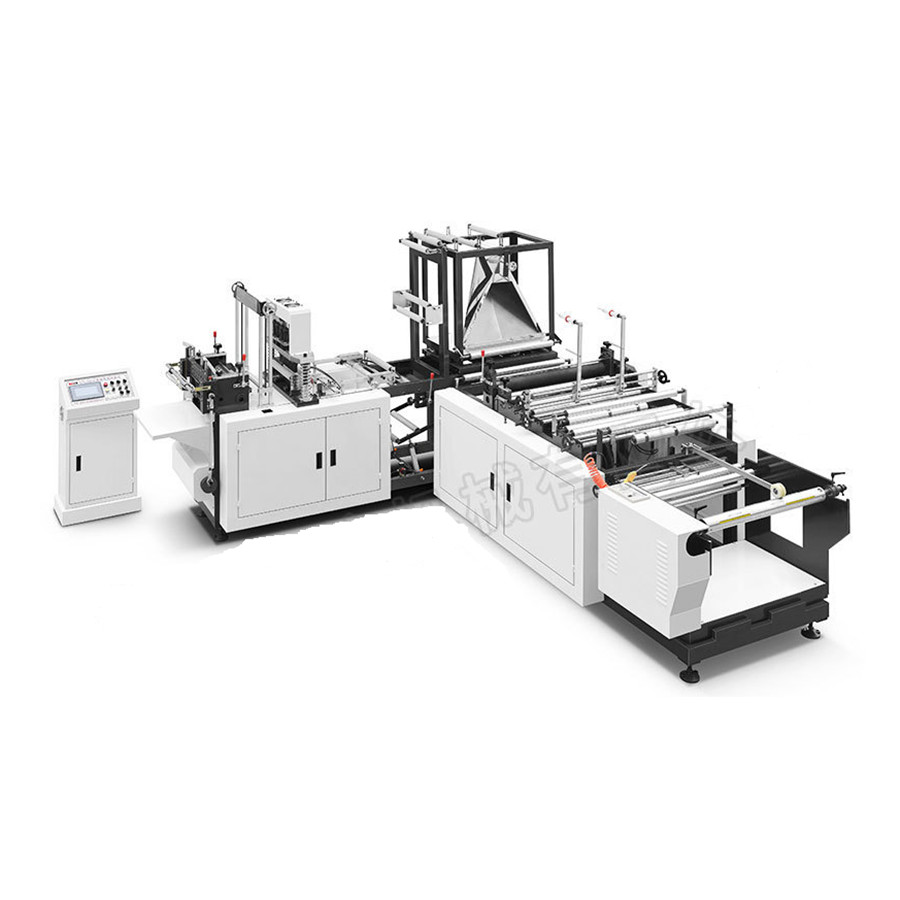

Non-woven Laminated Box Bag Making Leader Machine

This machine adopts mechanical, optical, electrical and pneumatic integration technology, suitable for feeding the roll material of non-woven fabric and laminated non-woven fabric. It’s a specialized equipment for making the primary shaping non-woven(laminated) three dimensional bag(no need to turn the bag inside out). This equipment features stable production, strong and decent sealing of bags, good looking, top grade, fancy and reusable, mainly applied in the field of non-woven wine packing, beverage packing, gift bags and hotel promotional bags etc.

This machine adopts LCD touch screen and equipped with stepping motor for fix length, photoelectric tracking, auto positioning and auto rectifying deviation, which is accurate and stable, has the function of auto counting, auto handle sealing, auto bag pile and auto alarming when reach the setting numbers etc. It is the most advanced equipment for non-woven bag making in the market at present.

-with multi size box bag forming and auto bag collecting

-with the function of turning handle inside and online handle attaching

-with laminated non woven material feeding

-with Taiwan Delta servo motor systems and PLC

Type of bags made by this machine

|

Min Size |

Max Size |

|

|

A |

180mm |

500mm |

|

B |

200mm |

450mm |

|

C |

80mm |

200mm |

|

D |

30mm |

80mm |

|

E |

110mm |

200mm |

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for China High Quality S/Ss/Sms Pp Spunbond Nonwoven Machine – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY , The product will supply to all over the world, such as: Jordan, Pretoria, Angola, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.