China High Quality Sanitary Pad Machine Semi Automatic Manufacturers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY

China High Quality Sanitary Pad Machine Semi Automatic Manufacturers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY Detail:

Ⅲ.main point

1. Adapt PLC control the whole machine, operate the machine by touch screen

2. the conveyor belt can absorb the product, when it is run high speed, it will not fly

3. Cutter adapt pressure spring protect the knife from overload pressure

4. edge sealing ADL and cutter adapt the air cylinder protect the device

5. Main machine adapt frequency control the speed

6. main machine adapt bearing, timing belt, right angle gearbox, eruptional box drive

7. Cutter, ADL, edge sealing, easy quick package adapt carding strengthen by the drive

8. Universal coupling guarantee high speed drive is stable

9.Floor and wall made by 20mm steel plate, the base made by 120*120mm square steel pipe to guarantee the stable

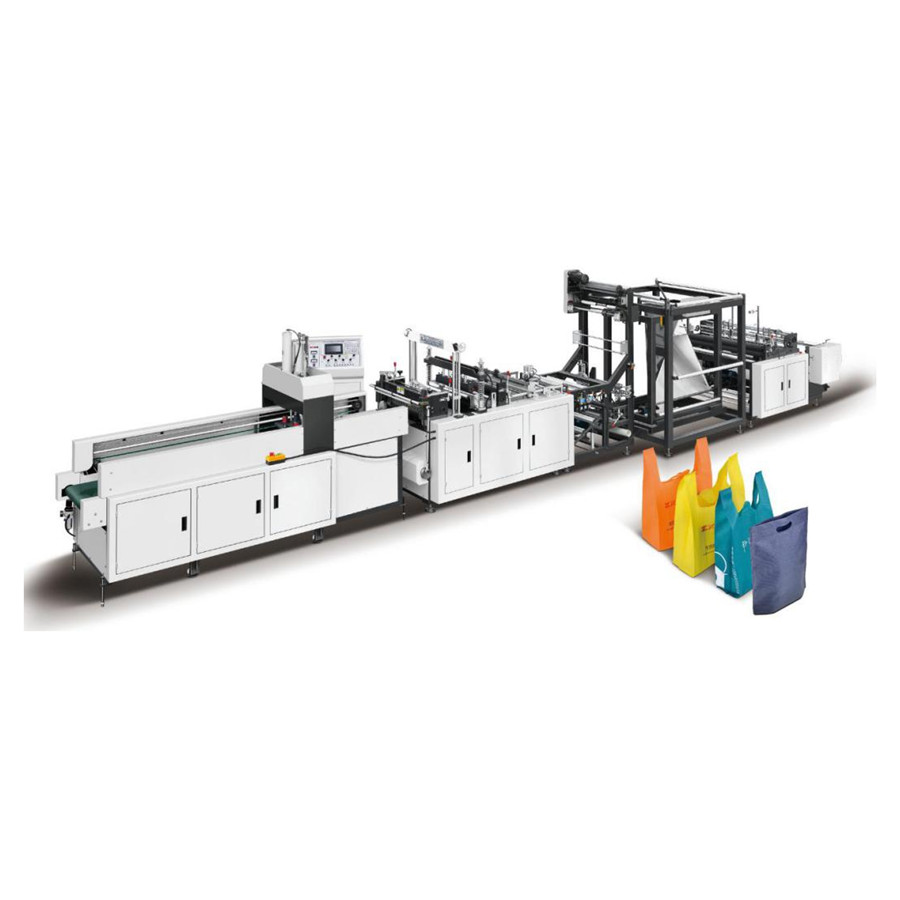

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for China High Quality Sanitary Pad Machine Semi Automatic Manufacturers – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY , The product will supply to all over the world, such as: Argentina, Italy, Portugal, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

Write your message here and send it to us