China High Quality Printer Machine Factory – 4 Colors flexo printing machine – MACHINERY

China High Quality Printer Machine Factory – 4 Colors flexo printing machine – MACHINERY Detail:

Main Configration

plate thickness:1.7mm

Paste Version Tape Thickness:0.38mm

Substrate Thickness:40-350gsm paper

Machine Color:Grey White

Operating Language:Chinese and English

Lubrication System:Automatic Lubrication System–Adjustable lubricationtime and quantity.when there is insufficient lubrication or system failure,the indicator lamp will automatically alarm.

Operating Console:Infront of the printing group

Air Pressure required:100PSI(0.6Mpa),Clean,Dry,Oil-free compressed air.

Power Supply:380V±10% 3PH 相50HZ

Tension Control Range:10-60KG

Tension Control Precision:±0.5kg

Printing Roller:2 sets for free(The number of teeth is up to customer)

Anilox roller(4pcs,Mesh is up to customer)

Drying:Infrared Dryer

The highest tempreture of heating dryer:120℃

Main drive: Asynchronous servo motor with gears

NSK,NAICH,CCVI,UBC。 Bearing Adopted famous brand such as NSK,NAICH,CCVI,UBC.

Second Drive gear:20CrMnTi,Good wear resistance,High hardness and toughness, long service life

PARAMETERS

|

No. |

parameters |

HSR-1000 |

| 1 | Max unwinding diameter | 1400mm |

| 2 | Max rewinding diameter | 1400mm |

| 3 | Printing Circumference | 317.5-952.5mm |

| 4 | Max web width | 1020mm |

| 5 | Max printing width | 1000mm |

| 6 | Register precision | ±0.1mm |

| 7 | printing gear | 1/8CP,3.175 |

| 8 | lubrication system | automatic |

| 9 | power supply | 380V 3PH 50HZ |

| 9 | working speed | 0-150m/min |

| 11 | Plate thickness | 1.7mm |

| 12 | Tape thickness | 0.38mm |

| 13 | Thickness of paper | 40-350gsm |

| 14 | Frame | 65mm |

| 15 | Automatic protection of paper breakage | yes |

| 16 | less paper automatic slow down | yes |

| 17 | automatic stop when Preset output finished | yes |

| 18 | meter counter | yes |

| 19 | Multi-speed adjustable | yes |

| 19 | Transfer gear | mateial is 20CrMnTi,hardness is 58 |

| 20 | machine color | Grey and white |

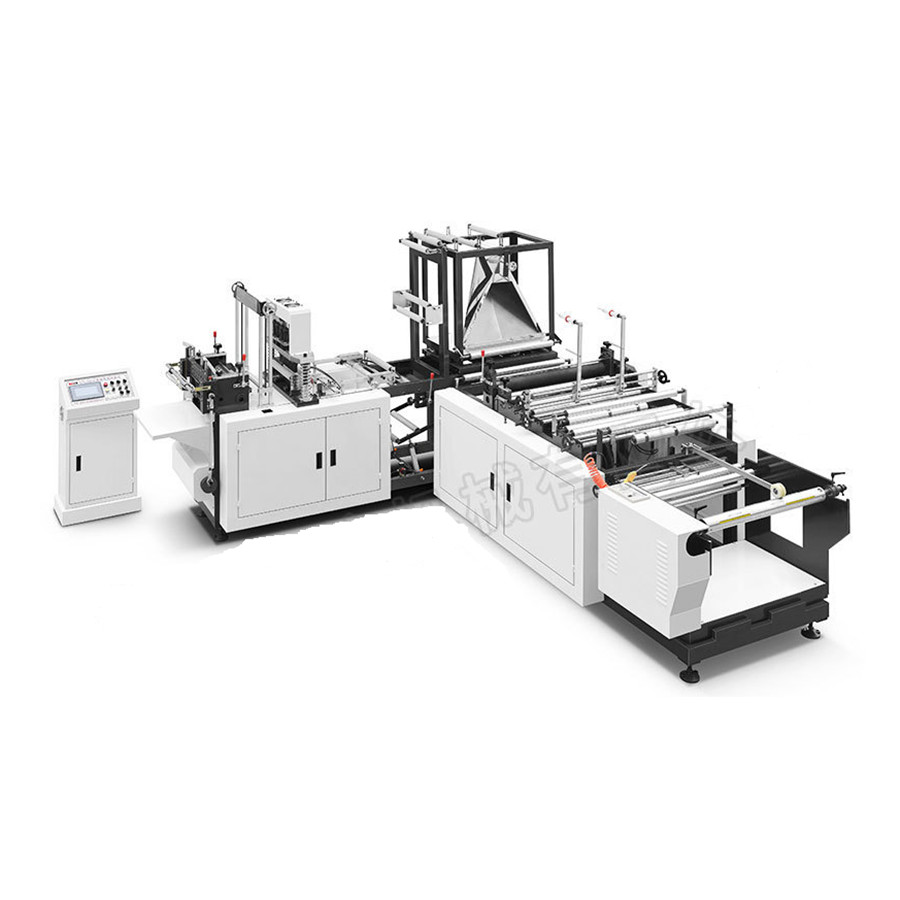

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China High Quality Printer Machine Factory – 4 Colors flexo printing machine – MACHINERY , The product will supply to all over the world, such as: Zambia, Qatar, New Zealand, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.