China High Quality Perforating Machine Factories – S non woven fabric production line – MACHINERY

China High Quality Perforating Machine Factories – S non woven fabric production line – MACHINERY Detail:

C. Public project

1. Water supplication

Pressure 2-4Bar

Temperature ≤28℃ PH : 6.5~9.2 Turbidity <10PPm

2. Compressed air

Operation pressure : 4-6Bar Allow range : ±0.2Bar

Dew point temperature :<25℃ Prevision : 1m3

A. Characteristics

| model no | 1600MM S | 2400MM S | 3200MM S |

| Capacity | 4-6 T/ DAY | 5-7 T/DAY | 8-10 T/DAY |

| Voltage | 240V OR 415V/50HZ | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 350 kw | 400kw | 500kw |

| Running power | 300 kw | 360 kw | 480 kw |

| effective width | 1600MM | 2400MM | 3200MM |

| Motor | Siemens | Siemens | Siemens |

| PLC | Siemens | Siemens | Siemens |

| Drive | Japan | Japan | Japan |

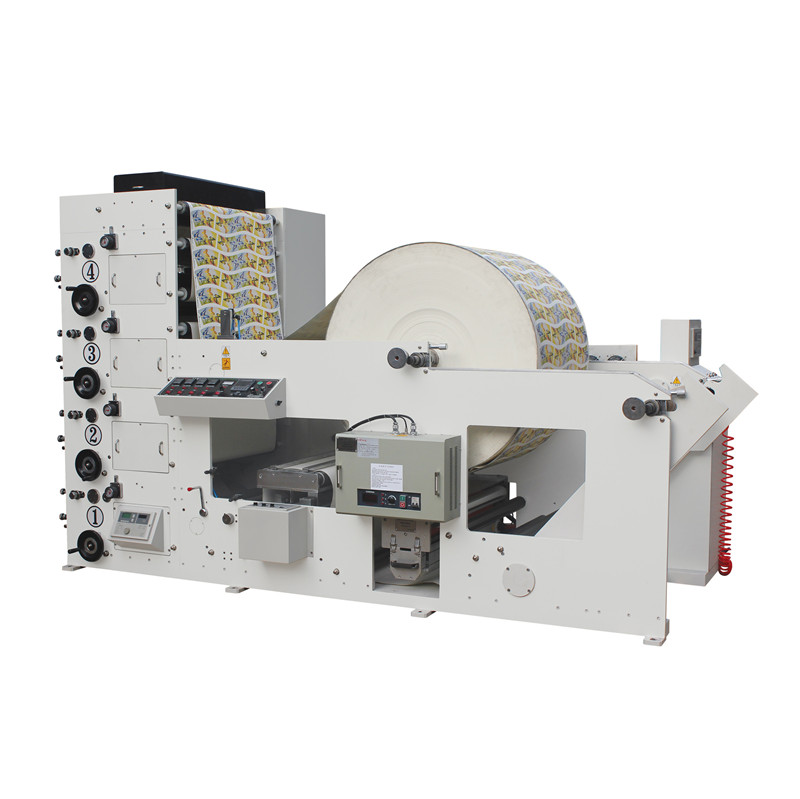

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for China High Quality Perforating Machine Factories – S non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: Bandung, Madagascar, Venezuela, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Write your message here and send it to us