China High Quality Paper Cup Printer Manufacturers – 4 Colors flexo printing machine – MACHINERY

China High Quality Paper Cup Printer Manufacturers – 4 Colors flexo printing machine – MACHINERY Detail:

Main Configration

plate thickness:1.7mm

Paste Version Tape Thickness:0.38mm

Substrate Thickness:40-350gsm paper

Machine Color:Grey White

Operating Language:Chinese and English

Lubrication System:Automatic Lubrication System–Adjustable lubricationtime and quantity.when there is insufficient lubrication or system failure,the indicator lamp will automatically alarm.

Operating Console:Infront of the printing group

Air Pressure required:100PSI(0.6Mpa),Clean,Dry,Oil-free compressed air.

Power Supply:380V±10% 3PH 相50HZ

Tension Control Range:10-60KG

Tension Control Precision:±0.5kg

Printing Roller:2 sets for free(The number of teeth is up to customer)

Anilox roller(4pcs,Mesh is up to customer)

Drying:Infrared Dryer

The highest tempreture of heating dryer:120℃

Main drive: Asynchronous servo motor with gears

NSK,NAICH,CCVI,UBC。 Bearing Adopted famous brand such as NSK,NAICH,CCVI,UBC.

Second Drive gear:20CrMnTi,Good wear resistance,High hardness and toughness, long service life

PARAMETERS

|

No. |

parameters |

HSR-1000 |

| 1 | Max unwinding diameter | 1400mm |

| 2 | Max rewinding diameter | 1400mm |

| 3 | Printing Circumference | 317.5-952.5mm |

| 4 | Max web width | 1020mm |

| 5 | Max printing width | 1000mm |

| 6 | Register precision | ±0.1mm |

| 7 | printing gear | 1/8CP,3.175 |

| 8 | lubrication system | automatic |

| 9 | power supply | 380V 3PH 50HZ |

| 9 | working speed | 0-150m/min |

| 11 | Plate thickness | 1.7mm |

| 12 | Tape thickness | 0.38mm |

| 13 | Thickness of paper | 40-350gsm |

| 14 | Frame | 65mm |

| 15 | Automatic protection of paper breakage | yes |

| 16 | less paper automatic slow down | yes |

| 17 | automatic stop when Preset output finished | yes |

| 18 | meter counter | yes |

| 19 | Multi-speed adjustable | yes |

| 19 | Transfer gear | mateial is 20CrMnTi,hardness is 58 |

| 20 | machine color | Grey and white |

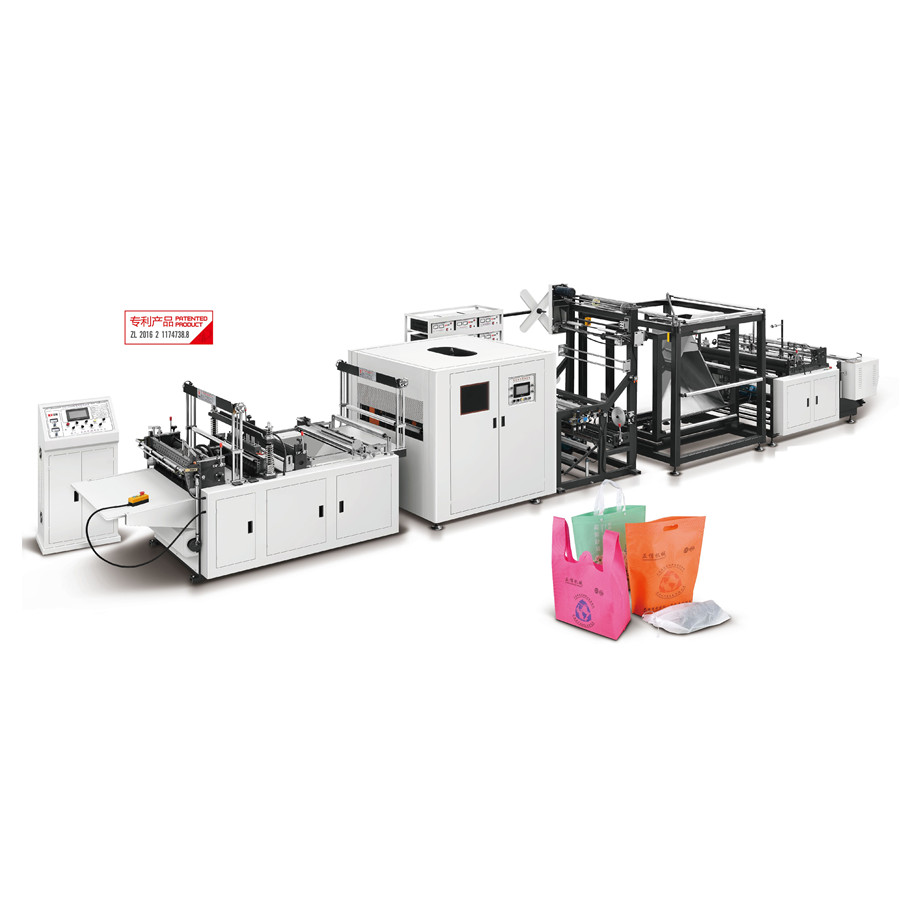

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for China High Quality Paper Cup Printer Manufacturers – 4 Colors flexo printing machine – MACHINERY , The product will supply to all over the world, such as: Malta, Philippines, South Africa, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!