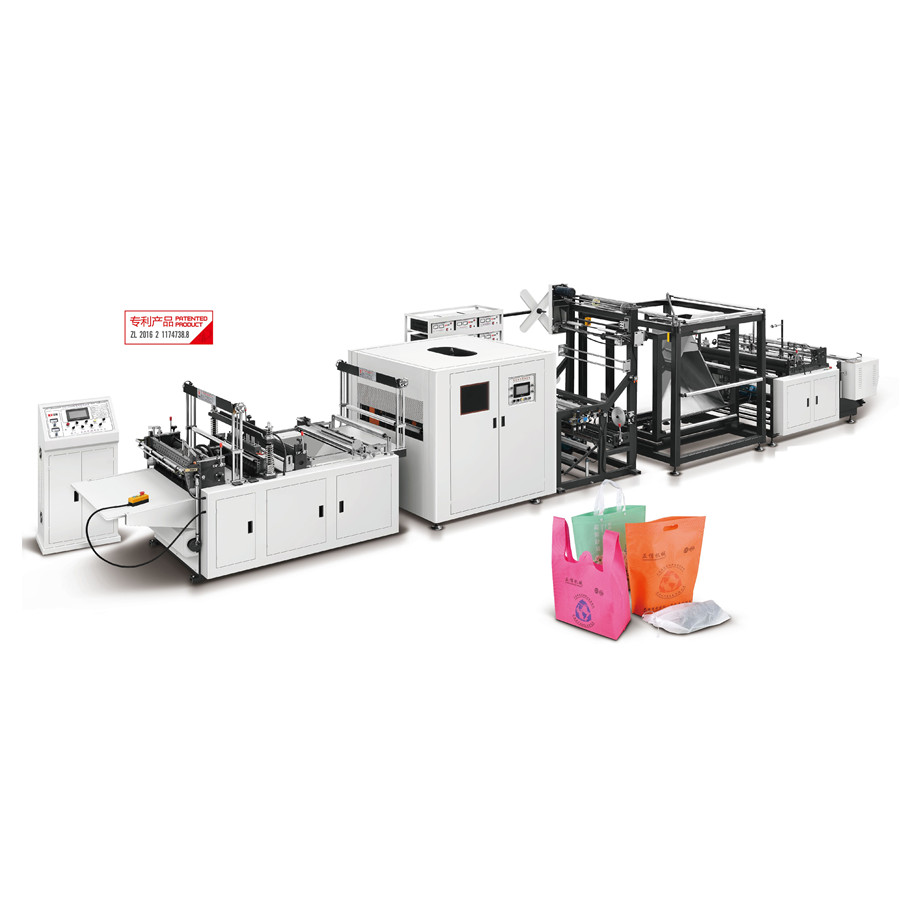

China High Quality Non Woven Box Bag Making Machine Manufacturers – Non-woven Bag Making Machine (6-in-1) – MACHINERY

China High Quality Non Woven Box Bag Making Machine Manufacturers – Non-woven Bag Making Machine (6-in-1) – MACHINERY Detail:

1)Fabric Roll Unwinding

Auto loading material roll(lift by cylinders)

Inflatable shaft to fix the fabric roll when machine working

Auto stop when material run out of

Magnetic powder tension controller

Auto rectifying deviation system(EPC box and web guider)

Bag mouth folding and sealing by ultrasonic welding

Cylinders to lift and fix the sealing mold

Custom-made sealing mould is available

2)Fabric Cross Folding

Stainless steel(triangular form) folding device Manual web guider

3)Bag Bottom Gusset And Side Gusset Forming – compressed air input here

Two sets round wheels for making bag bottom gusset and side gusset

The blower removes waste fabric

T-shirt bag sealing by ultrasonic welding

4)Online Handle Attaching – compressed air input here

Two set of ultrasonic welding systems with round embossing mold for handle feeding and sealing Four sets of ultrasonic welding systems for handle attaching Adjusted by touch screen Man machine interface:touch screen Motion control:PLC

5)Bag Side Sealing, Cutting, Collection

Adjustable photoelectric sensor for printing color mark tracking( it can be turned on/off on the touch screen)

Online D-cut punching, drawstring bag punching

Bag side sealing by ultrasonic welding system Durable cold cutter

Sealing mould with heating

device inside(temperature control by thermal indicator) static eliminator device Double stepping motor feeding system for bag

length fix

Man machine interface:touch screen

Motion control:PLC

Basic parameter

| Model no | LH-D700 |

| Bag width | 100-800mm |

| Bag Height | 200-600mm |

| Fabric gsm | 35-100g/m2 |

| Handle material gsm | 60-100g/m2 |

| Running speed | 20-120pcs/min |

| Power supply | 380v/20v |

| Total power | 15 kw |

| Machine size | 9600*2600*2100mm |

| Weight | 3400kgs |

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for China High Quality Non Woven Box Bag Making Machine Manufacturers – Non-woven Bag Making Machine (6-in-1) – MACHINERY , The product will supply to all over the world, such as: Mauritius, Nigeria, Brunei, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.