China High Quality High Productivity Automatic Flexo Custom Label Printing Machine Supplier – 6 color flexo printing machine – MACHINERY

China High Quality High Productivity Automatic Flexo Custom Label Printing Machine Supplier – 6 color flexo printing machine – MACHINERY Detail:

Control parts

1. Main motor frequency control, power

2. PLC touch screen control the whole machine

3. Reduce motor separate

UNWINDING PART

1. Single work station

2. Hydraulic clamp, hydraulic lift the material, hydraulic control

the unwinding material width, it can adjust left and right

movement.

3. Magnetic powder brake auto tension control

4. Auto web guide

PRINTING PART(4 pcs)

1. Pneumatic forward and backward clutch plate, stop printing plate and anilox roller to automatically backward, separate printing and inking, and then automatically transport ink. Start the alarm to start the

automatic printing plate and anilox roll to move forward automatically, close the stamping and inking, and print.

2. The printing plate roller is installed in English, and the sleeve type is loaded and unloaded from the side of the machine.

3. Inking with ceramic anilox with chambered doctor blade

4. The synchronous motor points 360 degree planetary gear box continuously and longitudinally, and the accuracy is as high as <0.15mm

5. One hand wheel is used to connect the inking pressure and the printing pressure, and the two measuring screws can be moved in and out at the same time, and both sides can be fine adjusted.

6.±0.2mm transverse register

DRYING PART

The first oven: after the PLC temperature module controls the external heating, the blower will supply hot air to 3 groups of drying channels. Each printing color group is dried.

The second oven: after the PLC temperature module controls the external heating, the blower sends hot air to the main drying channel for comprehensive drying

REWINDING PART

1. AC decelerating motor drives large roller for back friction winding

2. The vector converter of AC decelerating motor and the vector c

onverter of main engine adopt PLC synchronous control

3. High precision pressure reducing valve regulating tension

4. High precision pressure reducing valve regulates tightening pressure

5. 3 inch air shaft

6. Hydraulic lowering the material

| MODEL | ZYT6-1300 |

| Max. Printing material width | 1300mm |

| Max. Printing width | 1260mm |

| Max. Unwinding diameter | 1300mm |

| Max. Rewinding diameter | 1300mm |

| Printing length range | 228-1000mm |

| Printing speed | 5-100m∕min |

| Register precision | ≤±0.15mm |

| Thickness of plate(including the thickness of double sides glue) | Customer nominated |

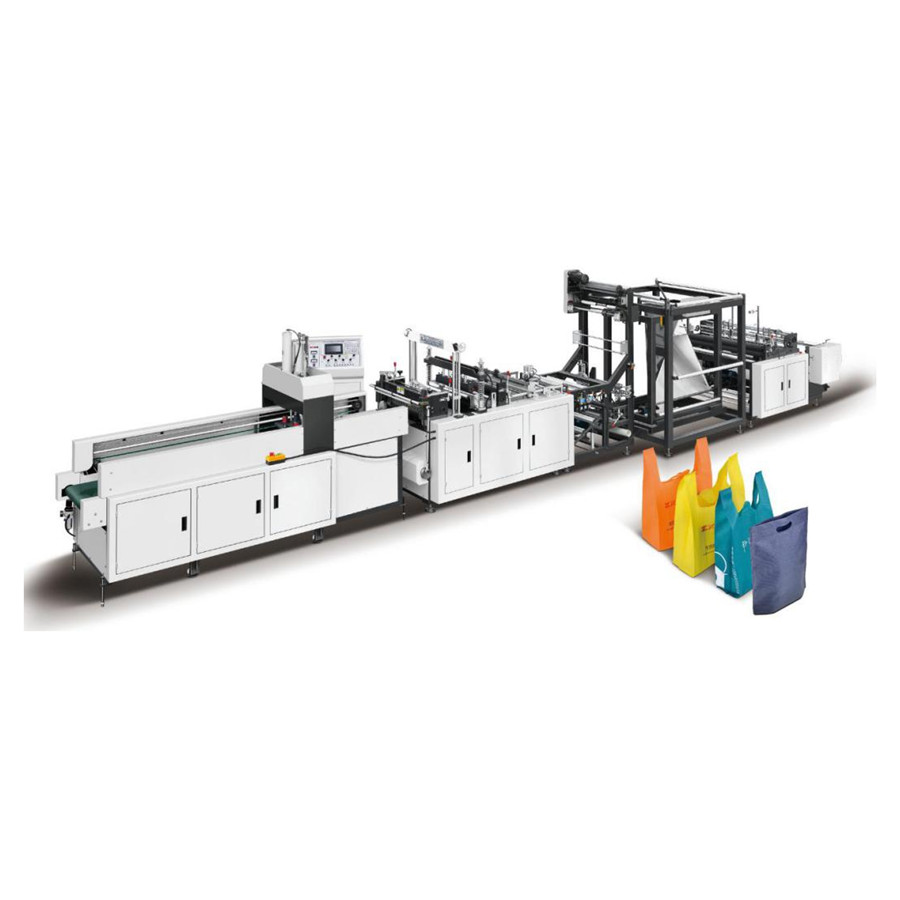

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with China High Quality High Productivity Automatic Flexo Custom Label Printing Machine Supplier – 6 color flexo printing machine – MACHINERY , The product will supply to all over the world, such as: Haiti, Barbados, New Orleans, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.