China High Quality Geotextile Machine – 1600MM SMS non woven fabric production line – MACHINERY

China High Quality Geotextile Machine – 1600MM SMS non woven fabric production line – MACHINERY Detail:

2 Process flow

Additive (recycle edge)

↓

Material→melting and extruding→filtering→metering→spinning→quenching→air-flow drawing

Material→melting and extruding→filtering→metering→spinning→hot air drawing→cooling→

web forming→calendering

Material→melting and extruding→filtering→metering→spinning→quenching→air-flow drawing

→winding and slitting

A. Main Equipment for Spunbond Section

1. Material hopper, 2sets

2. Suction, dosing and mixing device, 2sets

3. Extruder, 2sets

4. Spinning machine(spinneret from ENKA Germany), 2sets

5. Quenching and drawing system,2sets

6. Edge recycle extruder, 2sets

7. Web former, 1set

8. Winder (GUANGYU ), 1set

9. Slitter ( GUANGYU ), 1set

10. Steel frame for main machine, 1set

11. Electrical control system, 1set

B. Main Equipment for Meltblown Section

1. Storage hopper, 1set

2. Suction, dosing and mixing device, 1set

3. Extruder, 1set

4. Melt manifold, 1set

5. Die body (including spin pack), 1set

6. Electric (hot air) heating device, 1set

7. Roci fan blower(95m3/min; 0.12Mpa), 1set

8. Movable steel frame, 1set

9. Electrical control system, 1 set

Shaoyang will supply the cables from electrical control cabinet to main machine, Kurt Kumas will supply the cable tray and bridge.

C. Auxiliary Equipment

1. Pack oven, 1set

2. Pack ultrasonic cleaning machine, 1set

3. Lift for spin pack, 2 sets

4. Assembly and disassembly device for spin pack, 2 sets

5. Physical and chemical inspection device(test devices for denier control, water permability , strength control devices ), 1 set

6. Knife for cleaning the surface of spinning pack, 4 pcs

7. Torque spanner(60-300N.m), 2 sets

D. Utility Equipment

1. Chiller, 1 set

2. Cooling tower for air-conditione, 1 set

3. Cooling tower for others, 1 set

Air-conditioner, 2 sets

Suction blower, 3 sets

Cooling pump, 2 sets

Chilling pump, 4 sets

8. Compressed air system, 1 set

9. Oil heater (75Kw), 1 set

Flow char

3) Basic parameter:

| model no | 1600MM SMS | 3200MM SMS |

| Capacity | 9-11 T/ DAY | 12-17T/DAY |

| Voltage | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 1000 kw | 1800kw |

| Running power | 600 kw | 1000 kw |

| effective width | 1600MM | 3200MM |

| Motor | Siemens | Siemens |

| PLC | Siemens | Siemens |

| Drive | Japan | Japan |

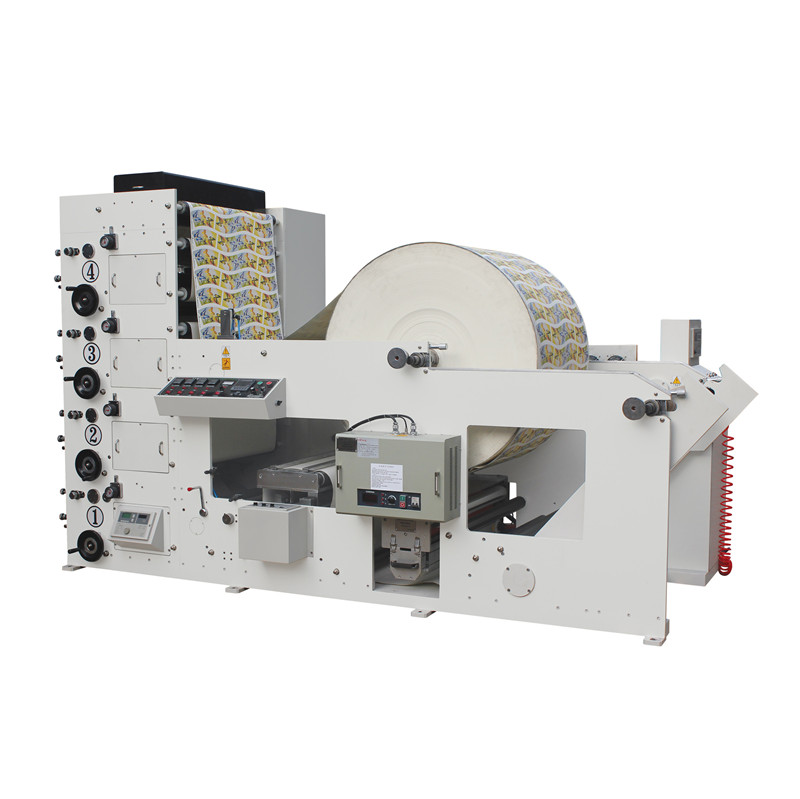

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for China High Quality Geotextile Machine – 1600MM SMS non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: Nepal, Belgium, Afghanistan, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!