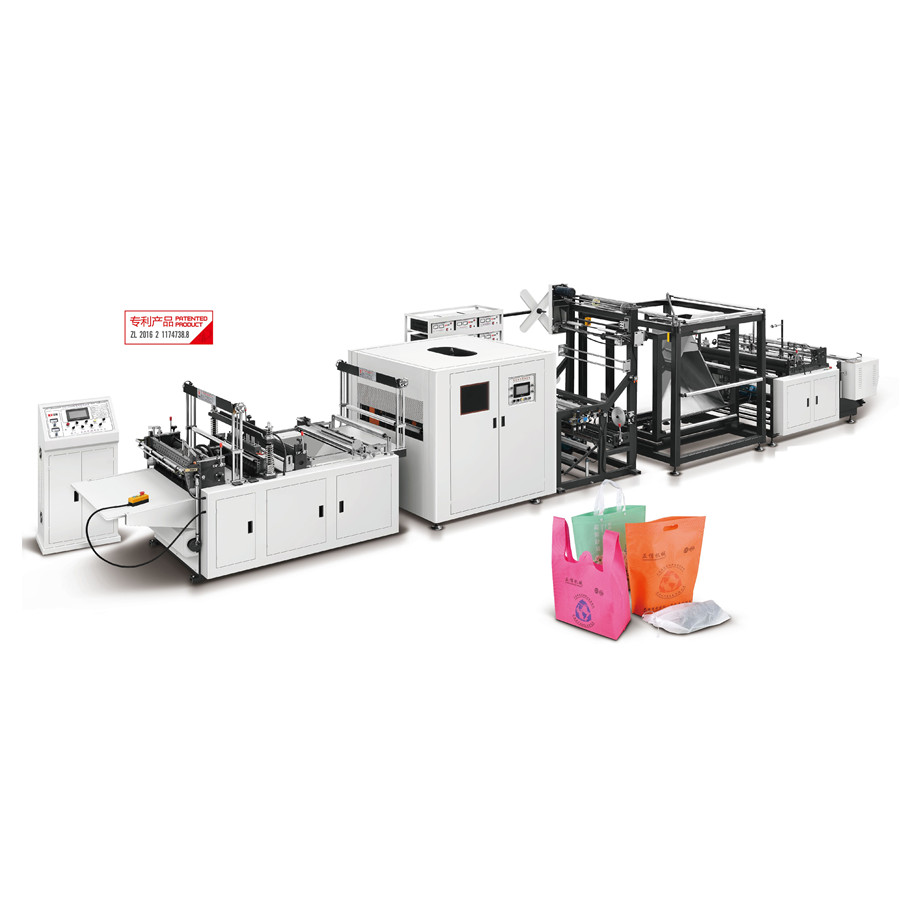

China High Quality Fully Automatic Nonwoven Bag Machinery Factory – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY

China High Quality Fully Automatic Nonwoven Bag Machinery Factory – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY Detail:

Model: ZX-LT500

Non-woven Laminated Box Bag Making Leader Machine

This machine adopts mechanical, optical, electrical and pneumatic integration technology, suitable for feeding the roll material of non-woven fabric and laminated non-woven fabric. It’s a specialized equipment for making the primary shaping non-woven(laminated) three dimensional bag(no need to turn the bag inside out). This equipment features stable production, strong and decent sealing of bags, good looking, top grade, fancy and reusable, mainly applied in the field of non-woven wine packing, beverage packing, gift bags and hotel promotional bags etc.

This machine adopts LCD touch screen and equipped with stepping motor for fix length, photoelectric tracking, auto positioning and auto rectifying deviation, which is accurate and stable, has the function of auto counting, auto handle sealing, auto bag pile and auto alarming when reach the setting numbers etc. It is the most advanced equipment for non-woven bag making in the market at present.

-with multi size box bag forming and auto bag collecting

-with the function of turning handle inside and online handle attaching

-with laminated non woven material feeding

-with Taiwan Delta servo motor systems and PLC

Type of bags made by this machine

|

Min Size |

Max Size |

|

|

A |

180mm |

500mm |

|

B |

200mm |

450mm |

|

C |

80mm |

200mm |

|

D |

30mm |

80mm |

|

E |

110mm |

200mm |

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for China High Quality Fully Automatic Nonwoven Bag Machinery Factory – Non-woven Laminated Box Bag Making Leader Machine – MACHINERY , The product will supply to all over the world, such as: Monaco, panama, El Salvador, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.