China High Quality Full Servo Sanitary Napkin Machinery Supplier – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY

China High Quality Full Servo Sanitary Napkin Machinery Supplier – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY Detail:

Ⅲ.main point

1. Adapt PLC control the whole machine, operate the machine by touch screen

2. the conveyor belt can absorb the product, when it is run high speed, it will not fly

3. Cutter adapt pressure spring protect the knife from overload pressure

4. edge sealing ADL and cutter adapt the air cylinder protect the device

5. Main machine adapt frequency control the speed

6. main machine adapt bearing, timing belt, right angle gearbox, eruptional box drive

7. Cutter, ADL, edge sealing, easy quick package adapt carding strengthen by the drive

8. Universal coupling guarantee high speed drive is stable

9.Floor and wall made by 20mm steel plate, the base made by 120*120mm square steel pipe to guarantee the stable

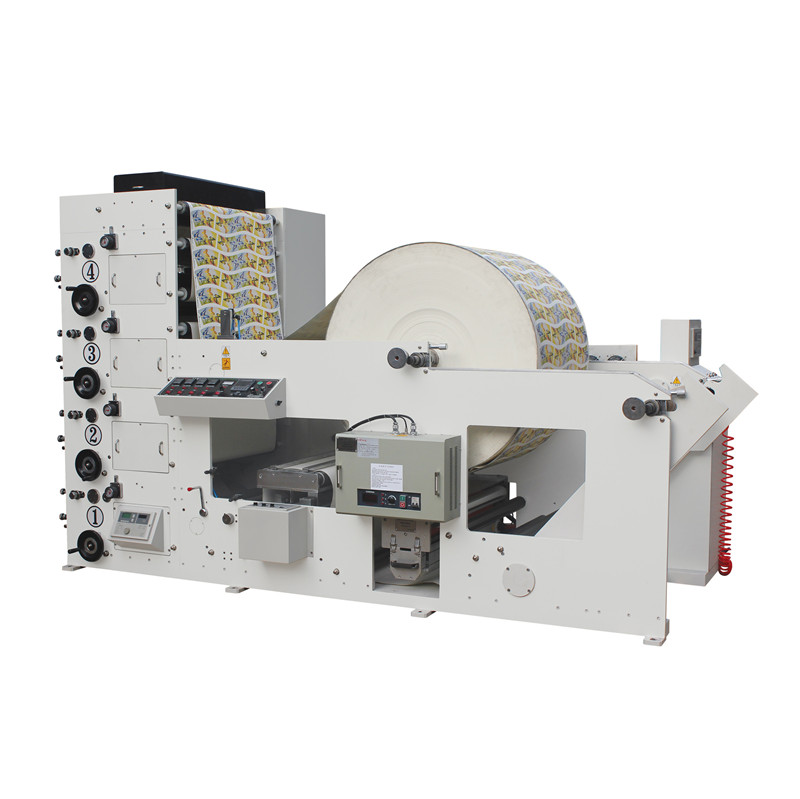

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for China High Quality Full Servo Sanitary Napkin Machinery Supplier – Auto Winged sanitary napkin Machine with quick-pack machine – MACHINERY , The product will supply to all over the world, such as: Canada, Chile, Roman, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us