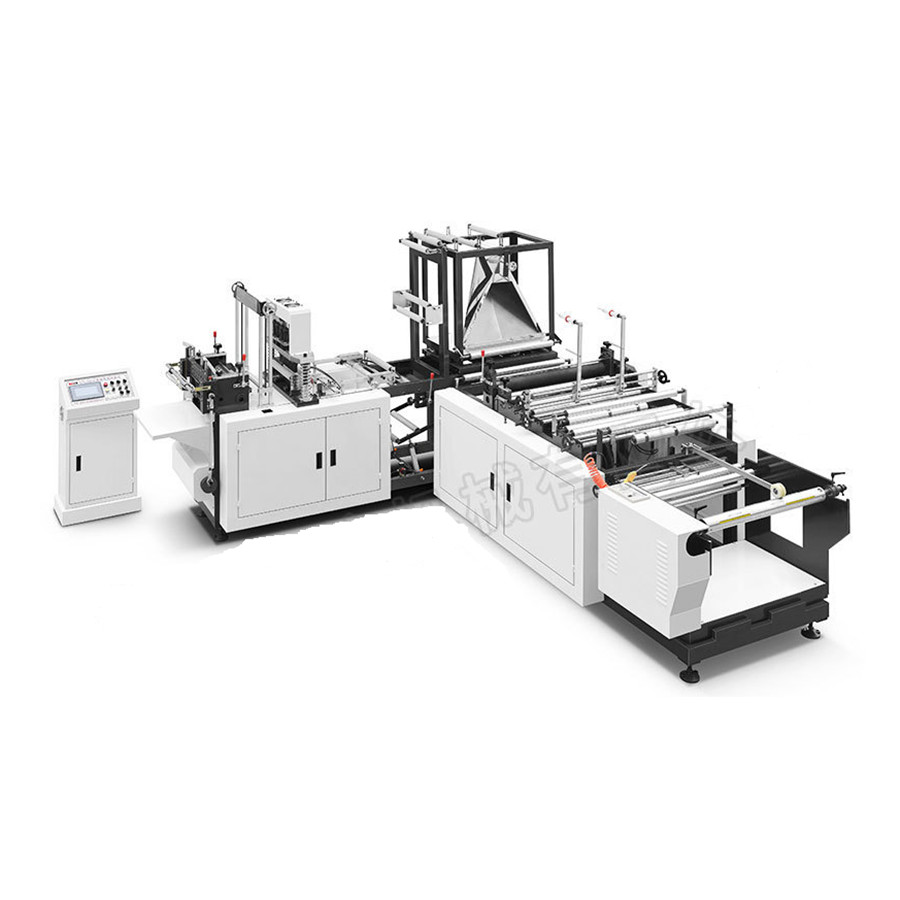

China High Quality Film Creasing And Perforating Machine – S non woven fabric production line – MACHINERY

China High Quality Film Creasing And Perforating Machine – S non woven fabric production line – MACHINERY Detail:

C. Public project

1. Water supplication

Pressure 2-4Bar

Temperature ≤28℃ PH : 6.5~9.2 Turbidity <10PPm

2. Compressed air

Operation pressure : 4-6Bar Allow range : ±0.2Bar

Dew point temperature :<25℃ Prevision : 1m3

A. Characteristics

| model no | 1600MM S | 2400MM S | 3200MM S |

| Capacity | 4-6 T/ DAY | 5-7 T/DAY | 8-10 T/DAY |

| Voltage | 240V OR 415V/50HZ | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 350 kw | 400kw | 500kw |

| Running power | 300 kw | 360 kw | 480 kw |

| effective width | 1600MM | 2400MM | 3200MM |

| Motor | Siemens | Siemens | Siemens |

| PLC | Siemens | Siemens | Siemens |

| Drive | Japan | Japan | Japan |

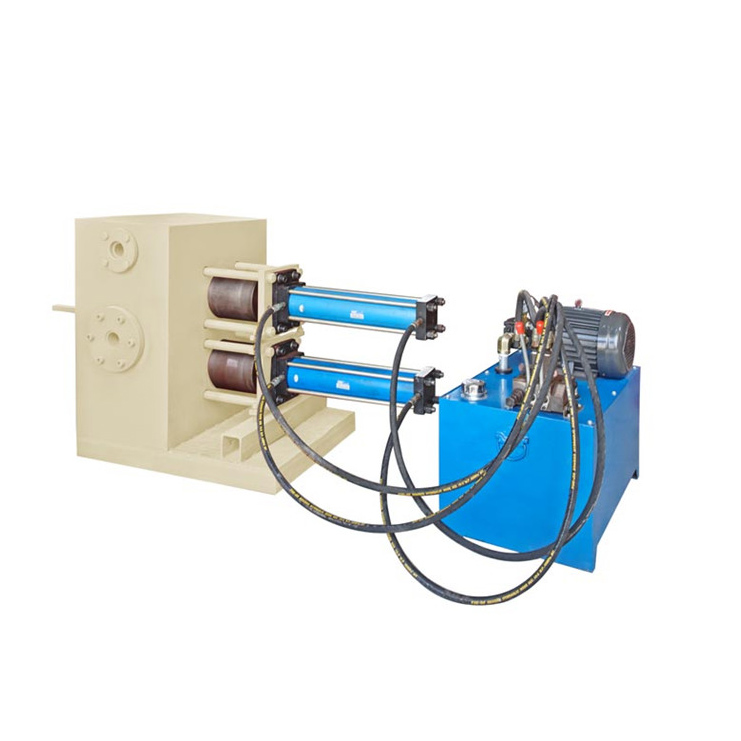

Product detail pictures:

Related Product Guide:

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for China High Quality Film Creasing And Perforating Machine – S non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: United States, Canberra, Germany, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Write your message here and send it to us