China High Quality Bag Making Machinery Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY

China High Quality Bag Making Machinery Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY Detail:

1. The machine is easy to operate and can produce paper handles with high speed usually reach 170 pairs per minute.

2. We design and offer the optional auto-production line, which can automatic gluing replace the human gluing procedure so that help to reduce lots of labor cost. It is strongly advice the paper bag producing factory use the auto-produce line that also support customize.

3. The unit paper bag can lift the heavy things of 15 kg at most, when the tension of raw materials reaches a certain level.

4. This machine adopts Huangshang melt-glue machine of Taiwan with service points in many countries, can provide customers with the fastest service.

Technical Data

|

Paper Roll Core Diameter |

Φ76 mm(3”) |

|

Max. Paper Roll Diameter |

Φ1000mm |

|

Production Speed |

10000pairs/hour |

|

Power Requirements |

380V |

|

Total Power |

7.8KW |

|

Total Weight |

Approx.1500kg |

|

Overall Dimension |

L4000*W1300*H1500mm |

|

Paper Length |

152-190mm(Optional) |

|

Paper Rope Handle Spacing |

75-95mm(Optional) |

|

Paper Width |

30/40mm |

|

Paper Rope Height |

100mm |

|

Paper Roll Diameter |

3.0-4mm |

|

Glue Type |

Hot-melt glue |

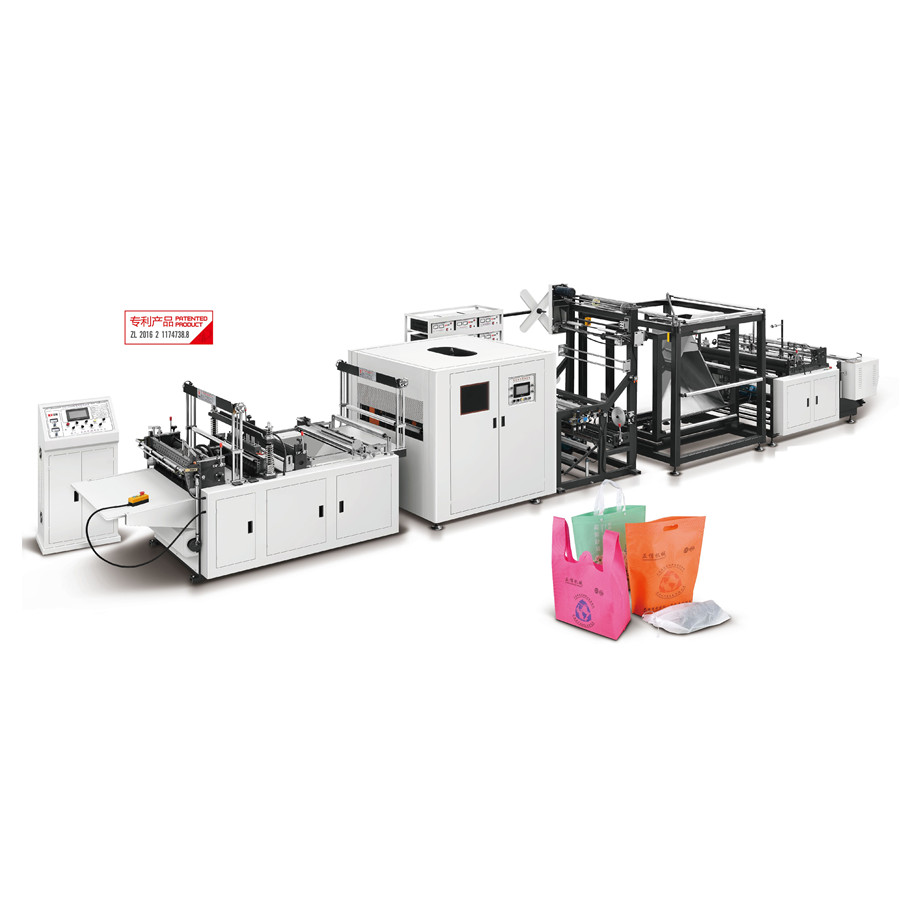

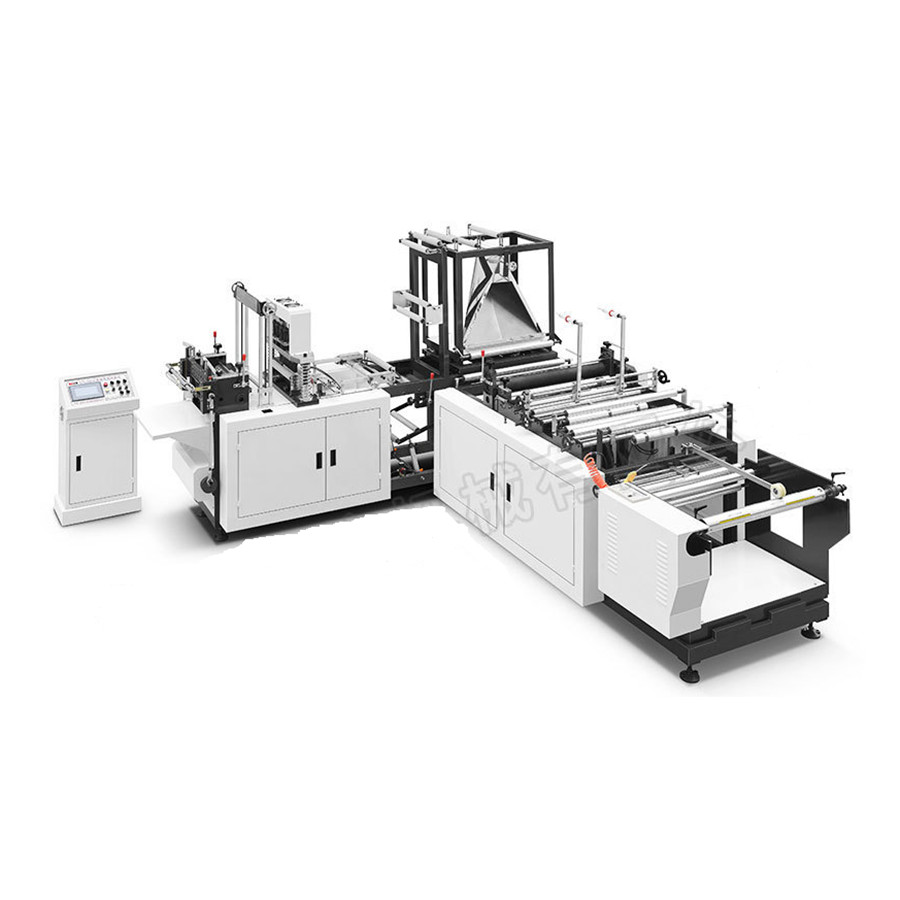

product picture

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for China High Quality Bag Making Machinery Factory – FY-10E hot melt glue twisted paper handle making machine – MACHINERY , The product will supply to all over the world, such as: Ethiopia, Lebanon, Spain, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!