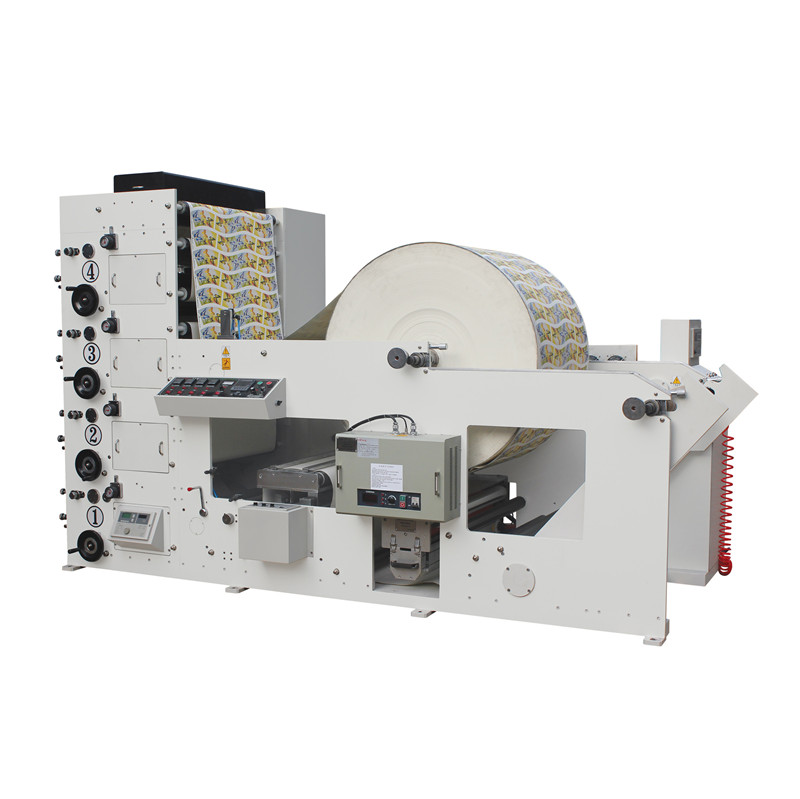

China High Quality 4 Color Paper Printing Machine Factories – 4 Colors flexo printing machine – MACHINERY

China High Quality 4 Color Paper Printing Machine Factories – 4 Colors flexo printing machine – MACHINERY Detail:

Main Configration

plate thickness:1.7mm

Paste Version Tape Thickness:0.38mm

Substrate Thickness:40-350gsm paper

Machine Color:Grey White

Operating Language:Chinese and English

Lubrication System:Automatic Lubrication System–Adjustable lubricationtime and quantity.when there is insufficient lubrication or system failure,the indicator lamp will automatically alarm.

Operating Console:Infront of the printing group

Air Pressure required:100PSI(0.6Mpa),Clean,Dry,Oil-free compressed air.

Power Supply:380V±10% 3PH 相50HZ

Tension Control Range:10-60KG

Tension Control Precision:±0.5kg

Printing Roller:2 sets for free(The number of teeth is up to customer)

Anilox roller(4pcs,Mesh is up to customer)

Drying:Infrared Dryer

The highest tempreture of heating dryer:120℃

Main drive: Asynchronous servo motor with gears

NSK,NAICH,CCVI,UBC。 Bearing Adopted famous brand such as NSK,NAICH,CCVI,UBC.

Second Drive gear:20CrMnTi,Good wear resistance,High hardness and toughness, long service life

PARAMETERS

|

No. |

parameters |

HSR-1000 |

| 1 | Max unwinding diameter | 1400mm |

| 2 | Max rewinding diameter | 1400mm |

| 3 | Printing Circumference | 317.5-952.5mm |

| 4 | Max web width | 1020mm |

| 5 | Max printing width | 1000mm |

| 6 | Register precision | ±0.1mm |

| 7 | printing gear | 1/8CP,3.175 |

| 8 | lubrication system | automatic |

| 9 | power supply | 380V 3PH 50HZ |

| 9 | working speed | 0-150m/min |

| 11 | Plate thickness | 1.7mm |

| 12 | Tape thickness | 0.38mm |

| 13 | Thickness of paper | 40-350gsm |

| 14 | Frame | 65mm |

| 15 | Automatic protection of paper breakage | yes |

| 16 | less paper automatic slow down | yes |

| 17 | automatic stop when Preset output finished | yes |

| 18 | meter counter | yes |

| 19 | Multi-speed adjustable | yes |

| 19 | Transfer gear | mateial is 20CrMnTi,hardness is 58 |

| 20 | machine color | Grey and white |

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for China High Quality 4 Color Paper Printing Machine Factories – 4 Colors flexo printing machine – MACHINERY , The product will supply to all over the world, such as: Amman, New Zealand, Cape Town, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.