Blanket Needle Punching Machine Manufacturers – S non woven fabric production line – MACHINERY

Blanket Needle Punching Machine Manufacturers – S non woven fabric production line – MACHINERY Detail:

C. Public project

1. Water supplication

Pressure 2-4Bar

Temperature ≤28℃ PH : 6.5~9.2 Turbidity <10PPm

2. Compressed air

Operation pressure : 4-6Bar Allow range : ±0.2Bar

Dew point temperature :<25℃ Prevision : 1m3

A. Characteristics

| model no | 1600MM S | 2400MM S | 3200MM S |

| Capacity | 4-6 T/ DAY | 5-7 T/DAY | 8-10 T/DAY |

| Voltage | 240V OR 415V/50HZ | 240V OR 415V/50HZ | 240VOR 415V/50HZ |

| Installed power | 350 kw | 400kw | 500kw |

| Running power | 300 kw | 360 kw | 480 kw |

| effective width | 1600MM | 2400MM | 3200MM |

| Motor | Siemens | Siemens | Siemens |

| PLC | Siemens | Siemens | Siemens |

| Drive | Japan | Japan | Japan |

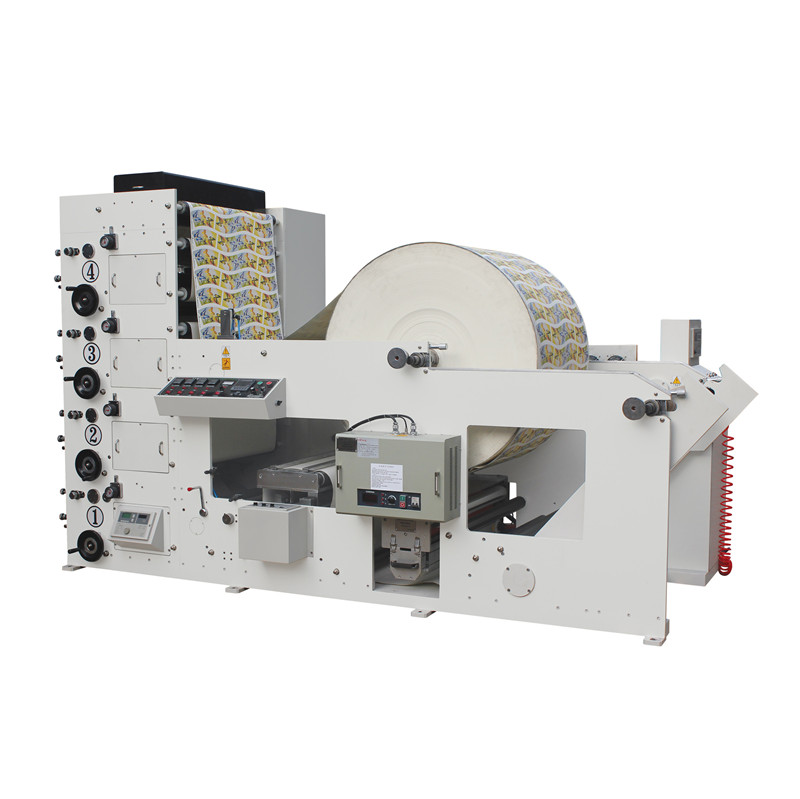

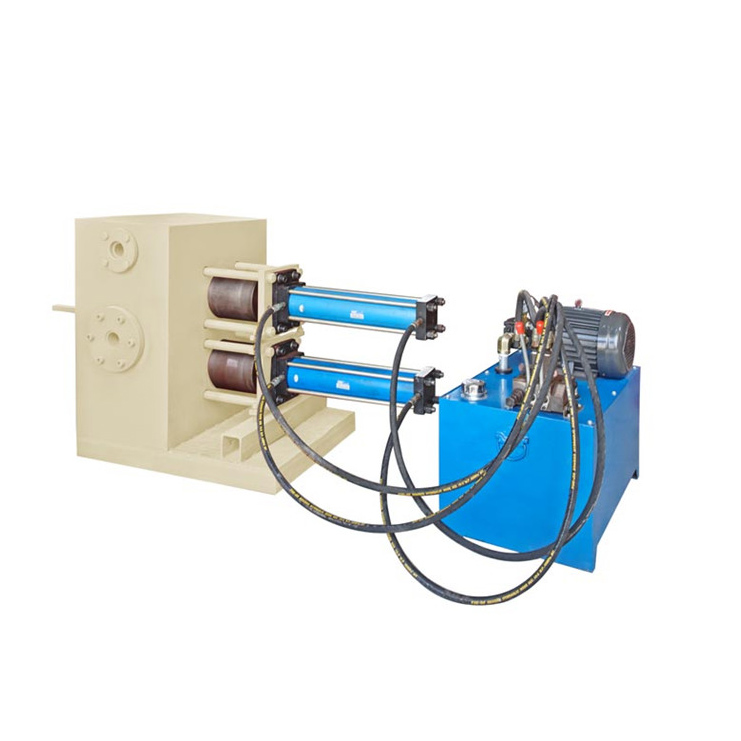

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for Blanket Needle Punching Machine Manufacturers – S non woven fabric production line – MACHINERY , The product will supply to all over the world, such as: Turin, Casablanca, Japan, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Write your message here and send it to us