Automatic Paper Plate Forming Machine Manufacturers – ML400J Hydraulic Paper Plate Making Machine – MACHINERY

Automatic Paper Plate Forming Machine Manufacturers – ML400J Hydraulic Paper Plate Making Machine – MACHINERY Detail:

| Model | ML400J |

| Diameter of Paper Dish | Large tray (mould replacement) |

| Capacity | 12-25Pcs/min (one working station) |

| Power Source | 380V 50HZ |

| Total Power | 7KW |

| weight | 1400Kg |

| Dimension | (L*W*H)2300*800*2000mm |

| Raw Material | According to the customers’ demands(original paper, white paperboard, white cardboard, aluminum foil paper or others) |

| Air Source | Working Pressure4.8Mpa

Working Air Volume 0.5m3/min |

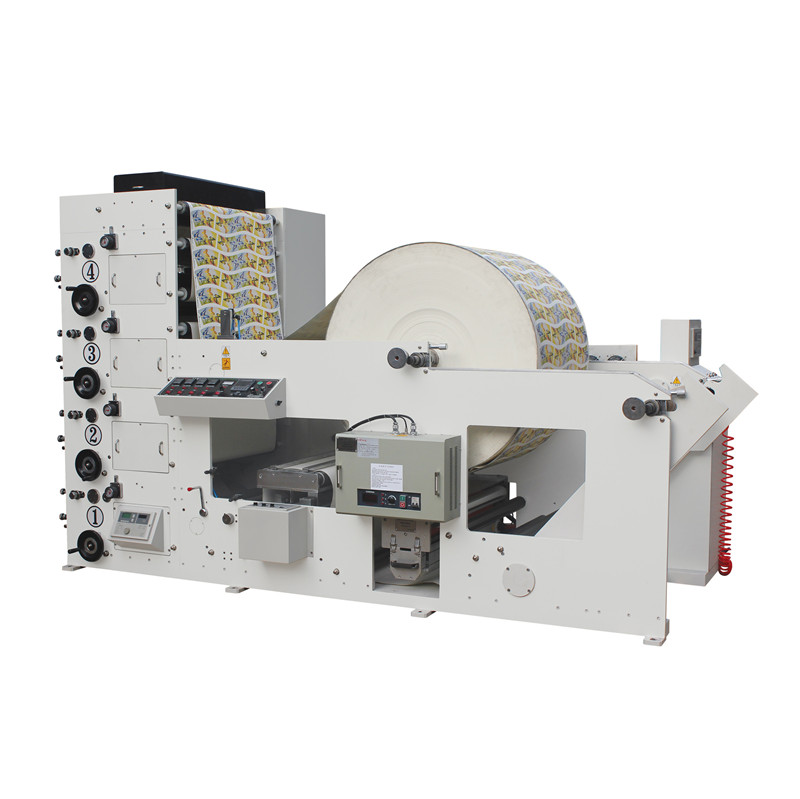

ML400J type super & intelligent paper plate machine is designed for large sized paper plate, it can make paper plate size from 4-19”, paper thickness from 180gsm to 3500gsm. Paper speed is about 12-25pcs/min, and the speed depends on your paper plate size and quality also. This machine adopts automatic paper suction, paper feeding and automatic forming which has advantages of safety, easy to operate and labor saving. It is the perfect machine for the larger sized paper plate which is widely used in parties and big banquets, and it is hygienic and environmental friendly.

Samples

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Automatic Paper Plate Forming Machine Manufacturers – ML400J Hydraulic Paper Plate Making Machine – MACHINERY , The product will supply to all over the world, such as: Adelaide, Cambodia, Borussia Dortmund, Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

Write your message here and send it to us