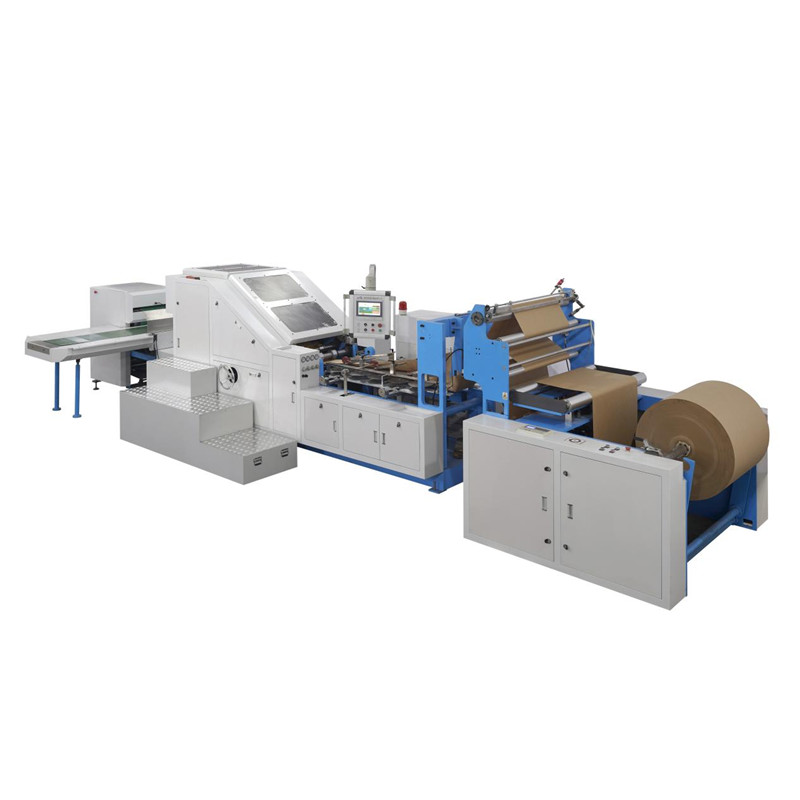

Automatic Bag Making Machine Manufacturers – High speed square bottom paper bag machine – MACHINERY

Automatic Bag Making Machine Manufacturers – High speed square bottom paper bag machine – MACHINERY Detail:

main feature

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts servo motor to reduce the adjustment time of paper roll alignment.

| Model | XL-FD450 |

| Cutting Length | 270-530mm |

| Paper Bag Width | 210-450mm |

| Bottom width | 90-180mm |

| Paper bag thickness | 80-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-150pcs/min |

| Paper roll width | 660-1290mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.6MPa |

| Total Weight | 9000kg |

| Overall size | 10000*3800*2200mm |

flow chart

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for Automatic Bag Making Machine Manufacturers – High speed square bottom paper bag machine – MACHINERY , The product will supply to all over the world, such as: Bangladesh, Liverpool, Ethiopia, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us