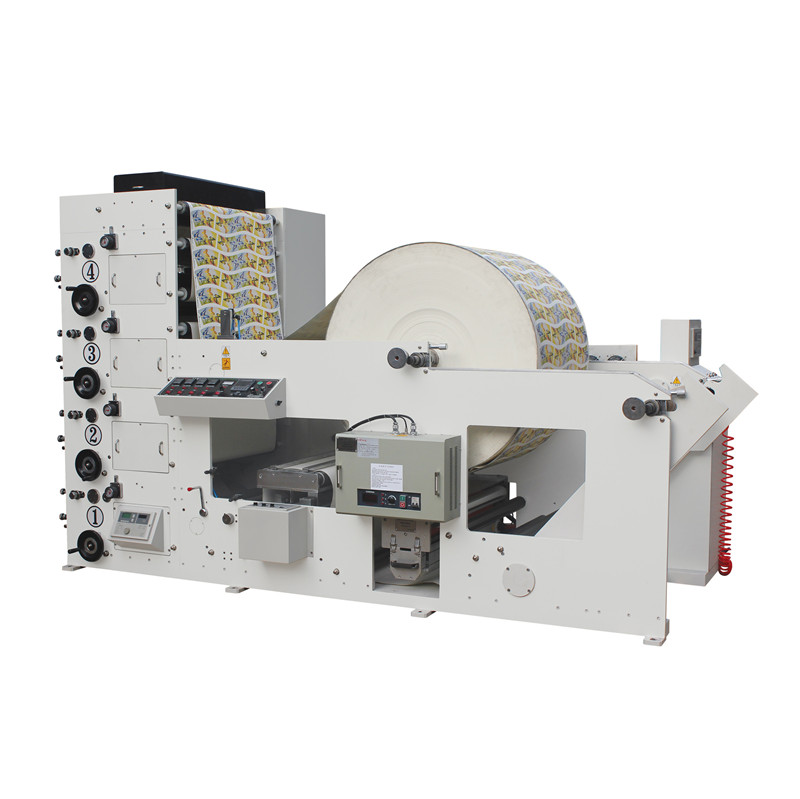

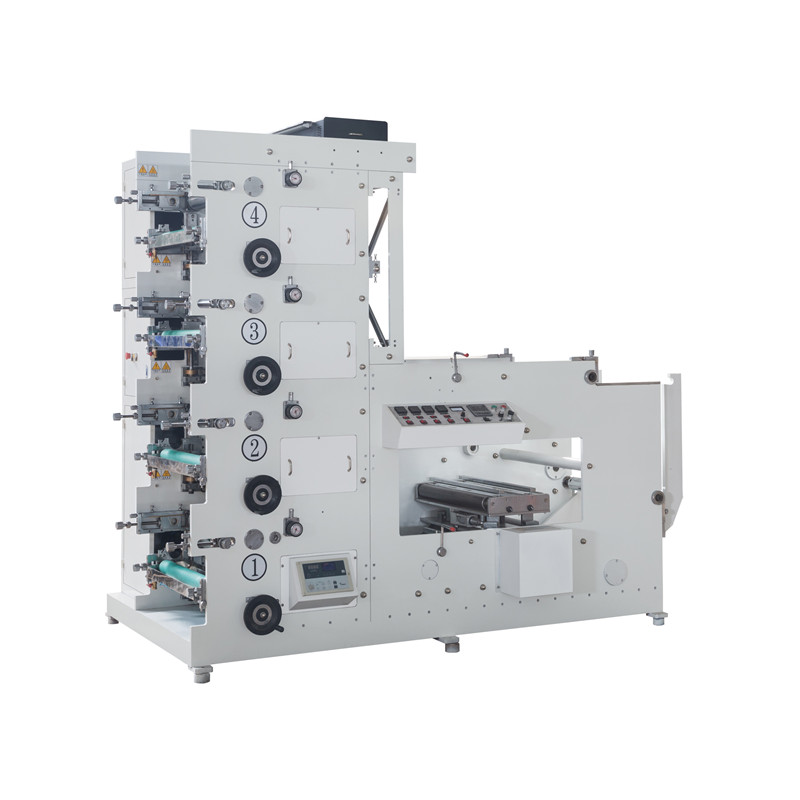

6 Color Flexo Printing Machine Factories – 4 color Paper Cup Printing Machine – MACHINERY

6 Color Flexo Printing Machine Factories – 4 color Paper Cup Printing Machine – MACHINERY Detail:

1.Main Configration

Substrate Thickness:50-400gsm paper

Machine Color:Grey White

Operating Language:Chinese and English

Power Supply:380V±10% 3PH 50HZ

Printing Roller:2 sets for free(The number of teeth is up to customer)

Anilox roller(4 pcs,Mesh is up to customer)

Drying:Infrared Dryer with 6pcs lamp

With big roller for surface rewinding

The highest tempreture of heating dryer:120℃

Main Motor:7.5KW

Total Power: 37KW

Unwinder Unit

• Max unwinding diameter 55inch(1400mm), with 3 inch roll axis core, including Automatic web guiding device,correct the position of paper automatically.With paper binding table and hydraulic lifting paper shaft device,and with Auto tension controller system

• 3inch Air swelling shaft core

• Electronic paper web guide traction device, there was a small offset paper web movement, the system can accurately continuously revised

• one Magnetic powder brake

• with fast inflatting gun

• Feeding tension unit:Taper control technology to ensure the regsiter precision.

Printing Unit

•Four colors printing unit,ceramic anilox roller, printing roller and embossing roller with high precision.

•The printing unit adopt 45 degree of DP13 helical gear structure.It can eliminated the vibration of the machine , to make it more stable and durable.

•Printing roller :8pcs(free)

•Ceramic Anilox roller: 4pcs(as require)

• Anilox roller, printing roller pressure pneumatic clutch

• Manual transverse focusing alignment 4 set

• Manual vertical focusing alignment 4 set

• Single pole reverse scraping system 4 set

• Stainless steel cartridge 4 set

• Fast changing plate cylinder without any tools

• Anilox roller rotation function: when machine stoped the anilox roller still running automatically, to prevent ink dry on anilox roller, avoid the anilox roller plug.

• The printing gear:cp1/8

Drying Unit

• Each printing group with IR dryer with 6pcs lamps ,controlled by independent switch,tempreture is adjustable.

• Hot wind and natural cold wind blowing combination.(including the suction blower)The incoming air volume is adjustable in each unit.

• Each printing group with hot air fans,ensure the quality of drying.(6 blowing and 1 suction)

Rewinder Unit

• A set of winding for rewinding after printing, with motor driven, ensure the stablity of rewinding tension and the precision of high speed running.

• with one 3inch rewind shaft core

Main Technical Parameters

|

NO. |

Model |

HSR-950-4 |

|

1 |

Max Unwinding Diameter |

1400mm |

|

2 |

Max Rewinding Diameter |

1400mm |

|

3 |

Printing Circumference |

254–508mm |

|

4 |

Max Web Width |

950mm |

|

5 |

Max Printing Width |

920mm |

|

6 |

Power supply |

380V 3PH 50HZ |

|

7 |

Printing Speed |

5-100m/min |

|

8 |

Plate thickness |

1.7mm |

|

9 |

Tape thickness |

0.38mm |

|

10 |

Thickness of paper |

50-400g |

|

11 |

Size |

5.2*2.05*2.3m |

|

12 |

Weight |

About6000kgs |

Main Parts

|

Name |

supplier |

|

Unwinding Tension |

CHUYIN TECH |

|

Rewinding Tension Converter |

Inovance |

|

Main motor converter |

|

|

Main Motor |

Shanghai 5.5KW |

|

Rewinding Motor |

shanghai |

|

EPC |

|

|

Switch Power |

Made in TaiWan |

|

Intermediate Relay |

|

|

Breaker |

|

|

Contactor |

|

|

Control Button |

|

|

Anilox roller |

Made in Shanghai |

|

Pneumatic Components |

QUOTATION

| name | specification | QTY | Note |

| Tempreture controller | 1 | ||

| IR lamp tube | 5 | ||

| Copper bush | 6 | ||

| Switch | 绿钮Green | 2 | |

| Switch | 黑钮Black | 2 | |

| Air cock | 2 | ||

| Hand wheel | 2 | ||

| Scraper | 5meters | ||

| Tape | 2meters | ||

| Solenoid Valve | 220v v210-08-DC220V | 1 | |

| belt | 2 |

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for 6 Color Flexo Printing Machine Factories – 4 color Paper Cup Printing Machine – MACHINERY , The product will supply to all over the world, such as: Stuttgart, luzern, Ukraine, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.